InterNACHI property inspectors are professional individuals who in exchange for a fee agree to accept the responsibility of evaluating and reporting on the interrelated conditions and components of a property with a “degree of care that a reasonably prudent home inspector would exercise,” Inspection is defined as “a non-invasive physical examination, performed for a fee in connection with the transfer … of a property,” undertaken in an attempt to identify “material defects” that could significantly “affect the value, desirability, habitability, or safety of the dwelling.” However, even this definition is subject to interpretation and debate, and what constitutes a InterNACHI inspection needs to be explained and clearly understood, for practical, ethical, and legal purposes. To borrow an example from medicine, an InterNACHI property inspector is similar to a general practitioner, who has learned a lot about medicine and the human body but has not specialized in any one particular discipline. Similarly, InterNACHI inspectors know a lot about the building trades, such as roofing, plumbing, heating, air-conditioning, and electrical, but they are not licensed specialists. In fact, like general practitioners, it is their responsibility to defer to specialists. For this reason, InterNACHI property inspections are limited in their scope.

InterNACHI property inspections are “non-invasive” and essentially visual and, as stated, are intended to alert consumers in a “written report” to “material defects” that exist at the time of an inspection, defects that could significantly affect the value of a property or pose a threat to health and safety. A property inspection is not technically exhaustive, and is not intended to be, and will not reveal every defect and deficiency. For instance, a property inspection does not include research to establish code-compliance, recall notices, or prior reports. Therefore, an inspection report should not be regarded as a substitute for the seller’s transfer disclosure statement (TDS), which the sellers are required to provide by the Business and Professions Code, or as an insurance policy, warranty, or guaranty. Some defects may be latent, and/or become apparent at a later point in time, which is why inspections have been sensibly characterized as snapshots in time. And it is essential that consumers understand this and, thereby, have reasonable expectations. However, the terms “non-invasive” and “visual” also need further explanation. For example, an inspector may remove the interior cover from an electrical panel, which could be said to be invasive, and inserting an electrical tester into a wall outlet could be construed as being more than a visual examination. Regardless, most inspectors remove cover panels and use a variety of specialized instruments in the service of their clients, but the use of such instruments does not distinguish them as specialists; only a licensing authority can legitimately confer that distinction. InterNACHI inspectors adhere to clearly defined standards and state laws, and to this extent InterNACHI standards are intended to be legally binding.

DEFINITIONS AND SCOPE

1.1.

A general home inspection is a non-invasive, visual examination of the accessible areas of a residential property (as delineated below), performed for a fee, which is designed to identify defects within specific systems and components defined by these Standards that are both observed and deemed material by the inspector. The scope of work may be modified by the Client and Inspector prior to the inspection process.

- The general home inspection is based on the observations made on the date of the inspection, and not a prediction of future conditions.

- The general home inspection will not reveal every issue that exists or ever could exist, but only those material defects observed on the date of the inspection.

1.2.

A material defect is a specific issue with a system or component of a residential property that may have a significant, adverse impact on the value of the property, or that poses an unreasonable risk to people. The fact that a system or component is near, at or beyond the end of its normal useful life is not, in itself, a material defect.

1.3.

A general home inspection report shall identify, in written format, defects within specific systems and components defined by these Standards that are both observed and deemed material by the inspector. Inspection reports may include additional comments and recommendations. Inspectors will report on required items only when a defect is found.

LIMITATIONS, EXCEPTIONS & EXCLUSIONS

2.1. Limitations for all inspections, including auxiliary services:

- An inspection is not technically exhaustive. This means that we do not diagnose the condition of components in a house beyond their function with normal operator controls. If a component does not work, further evaluation and/or repair will be noted in the report.

- An inspection does not guarantee a property will be free of defects, or that all defects will be reported/observed within a limited time frame and scope. There is no insurance nor coverage of any kind of repairs.

- An inspection will not identify concealed or latent defects. These are defects that are not apparent on the day of the inspection, or those defects that manifest after the inspection. An example is a furnace that works on the day of inspection, but fails after the inspection. Another example is a drain line that flows when the inspector runs clear water, but gets clogged with the use of toilet paper, soap, food items, etc.

- An inspection will not deal with aesthetic concerns or what could be deemed matters of taste, cosmetic defects, etc. Examples of excluded items includes paint, stains on flooring material, worn finishes on cabinets, doors, or decorator items such as curtains, curtain rods, blinds, etc.

- An inspection will not determine the suitability of the property for any use.

- An inspection does not determine the market value of the property or its marketability.

- An inspection does not determine the insurability of the property.

- An inspection does not determine the advisability or inadvisability of the purchase of the inspected property.

- An inspection does not determine the life expectancy of the property or any components or systems therein. Everything in a house can wear out. This includes appliances, HVAC equipment, roofing material, faucets and other plumbing fixtures, door locks and hardware, flooring, window hardware, etc. Just like an older car, parts wear out and a home inspection is not intended to determine the life remaining.

- An inspection does not include items not permanently installed. Examples include refrigerators, clothes washing and drying equipment, electrical equipment attached to a receptacle (timers, TV’s, water feature pumps, windows AC units, room heaters). * Building Supporters High-Performance standards include inspection and recall check (only when data is immediately available in database) including: Refrigerators, clothes washing and drying equipment, dishwashers, and trash compactors.

- These Standards of Practice apply only to properties with four or fewer residential units.

2.2.Exclusions:

- The inspector is not required to determine:

- Property boundary lines or encroachments.

- The condition of any component or system that is not readily accessible.

- The service life expectancy of any component or system.

- The size, capacity, BTU, performance or efficiency of any component or system. We rely on the builder having installed items according to codes in place at the time of construction. Inspectors do not calculate capacities or efficiency of any items such as HVAC equipment, pool heating and pumping equipment, solar (heating or PV).

- The cause or reason of any condition.

- The cause for the need of correction, repair or replacement of any system or component.

- Future conditions.

- Compliance with codes or regulations. Due to changing building codes on a nearly annual basis, it is impossible for a home inspector to know the exact codes in place at the time of construction. It is not reasonable to hold an older home to today’s building standards. While there are obvious right and wrong ways of installing items or building homes, we specifically do not cite codes within the scope of a home inspection.

- The presence of evidence of rodents, birds, animals, insects, or other pests.

- The presence of mold, mildew or fungus. * Building Supporters high-performance standards include a visual-only mold assessment. Building Supporters also offers an auxiliary mold testing service, which includes laboratory testing as an add-on service, for an additional fee.

- The presence of airborne hazards, including radon. Colorado has a high occurrence of Radon, and * Building Supporters therefore offers an auxiliary radon testing service as an add-on service, for an additional fee.

- The air quality.* Building Supporters offers air sampling and testing as an add-on service, for an additional fee.

- The existence of environmental hazards, including lead paint, asbestos or toxic drywall. * Building Supporters offers material sampling and testing as an add-on service, for an additional fee.

- The existence of electromagnetic fields.

- Any hazardous waste conditions.

- Any manufacturers’ recalls or conformance with manufacturer installation, or any information included for consumer protection purposes. * Building Supporters High-Performance standards include a recall check (only when data is immediately available in database) for: HVAC equipment, hot water heaters, refrigerators, clothes washing and drying equipment, dishwashers, and trash compactors.

- Acoustical properties. * Building Supporters High-Performance standards include a db level test for exhaust fans to report on operation performance.

- Correction, replacement or repair cost quotes.

- Quotes of the cost to operate any given system.

- The inspector is not required to operate:

- any system that is shut down.

- any system that does not function properly.

- or evaluate low-voltage electrical systems such as, but not limited to:

- Phone lines

- Cable lines

- Satellite dishes

- Antennae

- Lights

- Remote controls

- Any system that does not turn on with the use of normal operating controls.

- Any shut-off valves or manual stop valves.

- Any electrical disconnect or over-current protection devices. Home inspectors do not test circuit breakers to determine their effectiveness at times of over-load. A licensed electrician has the specialized tools for this. If you are buying an older home and are concerned about the functionality of breakers, you should have the electrical panel and the breakers tested by a licensed electrician.

- Any alarm systems.

- Moisture meters, gas detectors or similar equipment. * Building Supporters High-Performance standards include a general Infrared Thermography Survey and the use of moisture meters based on thermal findings. General gas leak detection is included in Building Supporters High-Performance standards; but does not include all gas pipes, only a representative sample.

III. The inspector is not required to:

- Move any personal items or other obstructions, such as, but not limited to: throw rugs, carpeting, wall coverings, furniture, ceiling tiles, window coverings, equipment, plants, ice, debris, snow, water, dirt, pets, or anything else that might restrict the visual inspection.

- Dismantle, open or uncover any system or component.

- Enter or access any area that may, in the opinion of the inspector, be unsafe. This is solely left to the discretion of the home inspector. An area may be deemed unsafe to enter due to limited clearance, animals, pests, standing water, poor electrical installations, animal waste, laceration hazards, or any other item deemed to be a hazard. This includes yards, side yards, crawl spaces, attics, rooms, garages, or storage rooms.

- Enter crawlspaces or other areas that may be unsafe or not readily accessible.

- Inspect underground items, such as, but not limited to: lawn-irrigation systems, underground storage tanks or other indications of their presence, whether abandoned or actively used.

- Do anything which may, in the inspector’s opinion, be unsafe or dangerous to the inspector or others, or damage property, such as, but not limited to: walking on roof surfaces, climbing ladders, entering attic spaces, or negotiating with pets.

- Inspect decorative items. This includes curtains, blinds, furniture, and hanging or stationary art.

- Inspect common elements or areas in multi-unit housing. If a component is not the property of the seller, it will not be inspected such as the roof of a condominium or townhouse, exterior stairs, pools, railings, stucco, decks, or any common area items.

- Inspect intercoms, speaker systems or security systems.

- Offer guarantees or warranties.

- Offer or perform any engineering services. This means that we do not calculate the load-bearing ability of any structure or determine any structural components for adequacy. Home inspectors rely on the builder having built the house to code and according to plans in place at the time of construction. If a part of the structure appears inadequate, the inspector will note it in the report for further evaluation. This includes deck structures, floor structures and roof structures.

- Offer or perform any trade or professional service other than general home inspection.

- Research the history of the property, or report on its potential for alteration, modification, extendibility or suitability for a specific or proposed use for occupancy.

- Determine the age of construction or installation of any system, structure or component of a building, or differentiate between original construction and subsequent additions, improvements, renovations or replacements.

- Determine the insurability of a property.

- Perform or offer Phase 1 or environmental audits.

- Inspect any system or component that is not included in these Standards.

STANDARDS OF PRACTICE

3.1. Roof

There are many roof types, and every roof will wear differently relative to its age, the number of its layers, the quality of its material, the method of its application, its exposure to direct sunlight or other prevalent weather conditions, and the quality and regularity of its maintenance. Regardless of its design-life, every roof is only as good as the waterproof membrane beneath it, which is concealed and cannot be examined without removing the roofing material, and this is equally true of most roofs. In fact, the material on the majority of pitched roofs is not designed to be waterproof only water-resistant. However, what remains true of all roofs is that, whereas their condition can be evaluated, it is virtually impossible for anyone to detect a leak except as it is occurring or by specific water tests, which are beyond the scope of the inspection and disclaimed. The inspector may walk the surface of a roof in order to inspect it and its components, but may inspect it by other means if the roof cannot be safely accessed, due to its height, weather conditions, or if the roofing material could be damaged by foot traffic.

- The inspector shall inspect from ground level or the eaves: We do not walk on roofs that have a wood shake, concrete tile, clay tile, or fragile composite tile covering, or those roofs that are greater than 17 feet from the ground, wet, excessively sloped, or for any reason may not be safe to mount. Inspector reserves the right to decline walking on any roof, for any reason. Building Supporters reserve the right to utilize aerial drones and/or pole cameras to perform roof inspections.

- the roof-covering materials;

- the gutters; Building Supporters’ high performance standards include reporting on readily-visible gutter debris/clogs.

- the downspouts;

- the vents, flashing, skylights, chimney, and other roof penetrations; and

- the general structure of the roof from the readily accessible panels, doors or stairs.

- The inspector shall describe:

- the type of roof-covering materials.

III. The inspector shall report as in need of correction:

- observed indications of active roof leaks. The term “indications” means any signs of a past leak including staining, damaged flashing, rot, etc. Some roof leaks may occur for which there was no indication, and those leaks could not be identified by a home inspector particularly after periods of dry weather.

- The inspector is not required to:

- walk on any roof surface.

- predict the service life expectancy.

- inspect underground downspout diverter drainage pipes.

- remove snow, ice, debris or other conditions that prohibit the observation of the roof surfaces.

- move insulation.

- inspect antennae, satellite dishes, lightning arresters, de-icing equipment, or similar attachments.

- walk on any roof areas that appear, in the opinion of the inspector, to be unsafe.

- walk on any roof areas if it might, in the opinion of the inspector, cause damage.

- perform a water test.

- warrant or certify the roof.

- confirm proper fastening or installation of any roof-covering material.

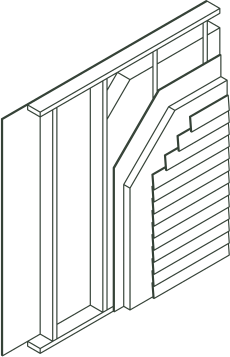

3.2. Exterior

It is important to maintain a property, including painting or sealing walls, walkways, decks, and other hard surfaces, because the cost of renovating a property will always exceed that of having maintained it. Regardless, it is particularly important for homeowners to keep building walls sealed, because they provide the primary barrier against the elements. Unsealed cracks at sill-plates and around windows, doors, and thresholds can permit moisture intrusion. Unfortunately, the evidence of such intrusion can be concealed by a coat of fresh paint and may only become obvious during rains or when water ponds, which is the primary reasons why a InterNACHI inspection should not be misinterpreted as a form of warranty or guarantee.

Positive grading and drainage are essential to the welfare of a property, and are usually the primary concern of architects and builders. Moisture can deteriorate most surfaces, and the ideal site will be graded to conduct water away from a building. In fact, the ideal building will be surrounded by hard surfaces that slope way from the exterior walls, the interior floors will be several inches higher than the exterior grade, and the building will have gutters and downspouts and a system of drainage designed to prevent any moisture from threatening the foundation or the living space. Unfortunately, many properties do not meet this ideal, conditions on most can generally be improved, and all need to be monitored and maintained to prevent damage. Also, inspectors cannot see inside area drains and do not water-test them, but they can become blocked by debris, occluded by silt, and damaged by movement. Therefore, buyers should question sellers about the functionality of any such system, have it serviced by a specialist, or assume the risk of having a system that does not function well and the damage that might result.

A home inspector cannot determine the effectiveness of grading and drainage during excessive rain or unusually heavy rain.

- The inspector shall inspect:

- the exterior wall-covering materials, flashing and trim;

- all exterior doors;

- adjacent walkways and driveways;

- stairs, steps, stoops, stairways and ramps;

- porches, patios, decks, balconies and carports;

- railings, guards and handrails;

- the eaves, soffits and fascia;

- a representative number of windows; and

- vegetation, surface drainage, retaining walls and grading of the property, where they may adversely affect the structure due to moisture intrusion.

- Building Supporters’ high performance standards include general measurement of readily-accessible window sill slopes, when a protruding slope is installed; representative sample only.

- The inspector shall describe:

- the type of exterior wall-covering materials.

III. The inspector shall report as in need of correction:

- any improper spacing between intermediate balusters, spindles and rails.

- The inspector is not required to:

- inspect or operate screens, storm windows, shutters, awnings, fences, outbuildings, or exterior accent lighting.

- inspect items that are not visible or readily accessible from the ground, including window and door flashing.

- inspect or identify geological, geotechnical, hydrological or soil conditions.

- inspect recreational facilities or playground equipment.

- inspect seawalls, breakwalls or docks.

- inspect erosion-control or earth-stabilization measures.

- inspect for safety-type glass.

- inspect underground utilities.

- inspect underground items.

- inspect wells or springs. * Building Supporters offers an auxiliary service as an add-on service, for an additional fee.

- inspect solar, wind or geothermal systems.

- inspect swimming pools or spas. * Building Supporters offers an auxiliary service as an add-on service, for an additional fee.

- inspect wastewater treatment systems, septic systems or cesspools. * Building Supporters offers an auxiliary service as an add-on service, for an additional fee.

- inspect irrigation or sprinkler systems.

- inspect drainfields or dry wells.

- determine the integrity of multiple-pane window glazing or thermal window seals. * Building Supporters High-Performance standards include a visual-only IGU integrity inspection, which looks for debris in the window seal. A representative sample only; does not include not all windows. A thermal inspection may be performed at the discretion of the inspector.

3.3. Basement, Foundation, Crawlspace & Structure

All foundations are dependent on the soil beneath them for support, but soils are not uniform. Some that might appear to be firm and stable can liquefy and become unstable during seismic activity. Also, expansive soils can expand to twice their volume with the influx of water and move structures with relative ease, raising and lowering them and cracking slabs and other hard surfaces. Regardless, foundations are not uniform, and conform to the structural standard of the year in which they were built. Therefore, the inspector will identify the foundation type and report on any evidence of significant deformation. However, cracks or deteriorated surfaces in foundations are common. In fact, it would be rare to find a raised foundation wall that is not cracked or deteriorated in some way, or a slab foundation that did not include some cracks concealed beneath the carpeting and padding. Regardless, InterNACHI inspectors cannot predict the future performance of any structure or its foundation, regardless of its age or type.

- The inspector shall inspect:

- the foundation;

- the basement;

- the crawlspace; and

- structural components.

- The inspector shall describe:

- the type of foundation; and

- the location of the access to the under-floor space.

III. The inspector shall report as in need of correction:

- observed indications of wood in contact with or near soil;

- observed indications of active water penetration;

- observed indications of possible foundation movement, such as sheetrock cracks, brick cracks, out-of-square door frames, and unlevel floors; and

- any observed cutting, notching and boring of framing members that may, in the inspector’s opinion, present a structural or safety concern.

- The inspector is not required to:

- enter any crawlspace that is not readily accessible or where entry could cause damage or pose a hazard to the inspector. * Building Supporters High-Performance standards include the use of crawlspace bot when obstructive or hazardous conditions are not present. Crawlspace bot has limitations and the inspector has sole discretion to mark as inaccessible area or operate crawlspace bot; operation is not guaranteed.

- move stored items or debris.

- operate sump pumps with inaccessible floats. Building Supporters high performance standards include visual-only inspection of readily-accessible sump pumps.

- identify the size, spacing, span or location or determine the adequacy of foundation bolting, bracing, joists, joist spans or support systems.

- provide any engineering or architectural service.

- report on the adequacy of any structural system or component.

3.4. Heating

The components of most heating and air-conditioning systems in Colorado have a design-life ranging from ten to twenty years, depending on the climate zone and the extent of their use, but can fail prematurely with poor maintenance. Inspectors test and evaluate them in accordance with the standards of practice, which means that they do NOT dismantle any of the following concealed components: heat exchangers, also known as the fireboxes or combustion chambers, electronic air-cleaners, humidifiers, and in-line duct motors or dampers. Similarly, they do not pressure-test components, and will not reverse the cycle on a heat pump if doing so might damage a coil. However, from the point of view of safety, you need to be aware that even the most modern fossil-fuel-burning systems can produce carbon monoxide, which in a sealed or poorly ventilated room can result in sickness, debilitating injury, and even death. Therefore, it is essential that any recommendation that is made for service or a second opinion be performed by a specialist, who might reveal additional defects or recommend some upgrades that could affect your evaluation of the system(s).

- The inspector shall inspect:

- heating system, using normal operating controls.

- The inspector shall describe:

- the location of the thermostat for the heating system;

- the energy source; and

- the heating method.

III. The inspector shall report as in need of correction:

- any heating system that did not operate; and

- if the heating system was deemed inaccessible.

- Building Supporters’ high performance standards include the general HVAC condenser pad slope level.

- The inspector is not required to:

- inspect or evaluate the interior of flues or chimneys, fire chambers, heat exchangers, combustion air systems, fresh-air intakes, humidifiers, dehumidifiers, electronic air filters, geothermal systems, or solar heating systems.

- inspect fuel tanks or underground or concealed fuel supply systems.

- determine the uniformity, temperature, flow, balance, distribution, size, capacity, BTU, or supply adequacy of the heating system.

- light or ignite pilot flames.

- activate heating, heat pump systems, or other heating systems when ambient temperatures or other circumstances are not conducive to safe operation or may damage the equipment.

- override electronic thermostats.

- evaluate fuel quality.

- verify thermostat calibration, heat anticipation, or automatic setbacks, timers, programs or clocks.

- Measure or calculate the air for combustion, ventilation, or dilution of the flue gases for appliances.

3.5. Cooling

- The inspector shall inspect:

- the cooling system using normal operating controls.

- The inspector shall describe:

- the location of the thermostat for the cooling system; and

- the cooling method.

III. The inspector shall report as in need of correction:

- any cooling system that did not operate; and

- if the cooling system was deemed inaccessible.

- The inspector is not required to:

- determine the uniformity, temperature, flow, balance, distribution, size, capacity, BTU, or supply adequacy of the cooling system.

- inspect portable window units, through-wall units, or electronic air filters.

- operate equipment or systems if the exterior temperature is below 65° Fahrenheit, or when other circumstances are not conducive to safe operation or may damage the equipment.

- inspect or determine thermostat calibration, cooling anticipation, or automatic setbacks or clocks.

- examine electrical current, coolant fluids or gases, or coolant leakage.

3.6. Plumbing

Plumbing systems have common components, but they are not uniform. In addition to fixtures, these components include gas pipes, water pipes, pressure regulators, pressure relief valves, shut-off valves, drain pipes, vent pipes, and water-heating devices. The water pressure in pipes is commonly confused with water volume, or functional flow, but whereas high volume may be desirable high pressure is not. In fact, whenever street pressure exceeds eighty pounds per square inch (PSI) a regulator is required, which typically comes factory preset between forty-five and sixty-five PSI. Consumers need to understand that leaks will occur in any system and particularly a system with older pipes or one in which a regulator fails and high pressure is able to stress the washers and diaphragms of components.

Waste and drainpipes are also not uniform, and range from a modern ABS type [acrylonitrile butadiene styrene] to older types made of cast-iron, galvanized steel, clay, and even a cellulose material that has been coated with tar (Orangeburg pipe). The condition of drainpipes is usually directly related to their age. Older ones are subject to damage through decay and root or seismic activity, whereas ABS ones are virtually impervious to damage. However, as significant portions of drainpipes are concealed, inspectors can only infer their condition by observing the draw at drains. Nonetheless, blockages and leaks will occur in the life of any system. Shower pans and bath tubs are flood-tested, but not guaranteed to never leak after testing. [See Section 12]. Blockages and leaks in main sewer pipes are common and are costly to repair or replace, and for this reason we sensibly disclaim responsibility for evaluating the concealed portions and strongly recommend that buyers arrange to have the main sewer pipe video-scanned, or accept the risk of any damage that might occur. * Building Supporters offers auxiliary water testing, well inspection, and sewer line scope service as add-on services, for additional fees.

- The inspector shall inspect:

- the main water supply shut-off valve;

- the main fuel supply shut-off valve;

- the water heating equipment, including the energy source, venting connections, temperature/pressure-relief (TPR) valves, Watts 210 valves, and seismic bracing;

- interior water supply, including all fixtures and faucets, by running the water;

- all toilets for proper operation by flushing;

- all sinks, tubs and showers for functional drainage;

- the drain, waste and vent system; and

- drainage sump pumps with accessible floats.

- Building Supporters’ high performance standards include a toilet tank dye test, performed at the inspectors sole-discretion. Excludes in-wall tank carriers.

- Building Supporters’ high performance standards include a general slope measurement for drains that are readily-visible; a representative sample only with limited sections measured.

- The inspector shall describe:

- whether the water supply is public or private based upon observed evidence;

- the location of the main water supply shut-off valve;

- the location of the main fuel supply shut-off valve;

- the location of any observed fuel-storage system; and

- the capacity of the water heating equipment, if labeled.

- Building Supporters’ high performance standards include reporting the whole-house water pressure using a standard hose bib, only if present, (limited to warm weather only) or an empty washer connection (must be readily accessible).

III. The inspector shall report as in need of correction:

- deficiencies in the water supply by viewing the functional flow in two fixtures operated simultaneously;

- deficiencies in the installation of hot and cold water faucets;

- mechanical drain stops that were missing or did not operate if installed in sinks, lavatories and tubs; and

- toilets that were damaged, had loose connections to the floor, were leaking, or had tank components that did not operate.

- The inspector is not required to:

- light or ignite pilot flames.

- measure the capacity, temperature, age, life expectancy or adequacy of the water heater.

- inspect the interior of flues or chimneys, combustion air systems, water softener or filtering systems, well pumps or tanks, safety or shut-off valves, floor drains, lawn sprinkler systems, or fire sprinkler systems.

- determine the exact flow rate, volume, pressure, temperature or adequacy of the water supply.

- determine the water quality, potability or reliability of the water supply or source.

- open sealed plumbing access panels.

- inspect clothes washing machines or their connections.

- operate any valve.

- test shower pans, tub and shower surrounds or enclosures for leakage or functional overflow protection. * Building Supporters High-Performance standards include filling and draining bath tubs. Neither serve as guarantee or warranty of a leak-free shower/bath tub.

- test tub jets. * Building Supporters High-Performance standards include filling and testing tub jets unless closed panels, non-accessible controls, or inspector, at their sole discretion cannot readily operate control display panels.

- evaluate the compliance with conservation, energy or building standards, or the proper design or sizing of any water, waste or venting components, fixtures or piping.

- determine the effectiveness of anti-siphon, back-flow prevention or drain-stop devices.

- determine whether there are sufficient cleanouts for effective cleaning of drains.

- evaluate fuel storage tanks or supply systems.

- inspect wastewater treatment systems.

- inspect water treatment systems or water filters.

- inspect water storage tanks, pressure pumps, or bladder tanks. * Building Supporters High-Performance standards include a visual-only check for signs of exterior tank corrosion.

- evaluate wait-time to obtain hot water at fixtures, or perform testing of any kind to water heater elements.

- evaluate or determine the adequacy of combustion air.

- test, operate, open or close: safety controls, manual stop valves, temperature/pressure-relief valves, control valves, or check valves.

- examine ancillary or auxiliary systems or components, such as, but not limited to, those related to solar water heating and hot water circulation.

- determine the existence or condition of polybutylene, polyethylene, or similar plastic piping. * Building Supporters High-Performance standards include a visual-only check and report for a general plumbing piping types, but does not/may not include specific material identification.

- inspect or test for gas or fuel leaks, or indications thereof * Building Supporters High-Performance standards include general gas leak detection testing; a representative sample only.

3.7. Electrical

There are a wide variety of electrical systems with an even wider variety of components, and any one particular system may not conform to current standards or provide the same degree of service and safety. What is most significant about electrical systems however is that the National Electrical Code is not retroactive, and therefore many electrical systems do not comply with the latest safety standards. It is important to remember that electricity is dangerous, and is best evaluated by a specialist and not a generalist. Inspectors are generalists, and do not perform load-calculations to see if the supply equals the demand, nor remove circuit breakers or cover plates to inspect concealed components. Therefore, in the interests of safety, every electrical deficiency and recommended upgrade should be regarded as a potential safety-hazard that should be serviced as soon as conveniently possible by a licensed specialist.

- The inspector shall inspect:

- the service drop;

- the overhead service conductors and attachment point;

- the service head, gooseneck and drip loops;

- the service mast, service conduit and raceway;

- the electric meter and base;

- service-entrance conductors;

- the main service disconnect;

- panelboards and over-current protection devices (circuit breakers and fuses);

- service grounding and bonding;

- a representative number of switches, lighting fixtures and receptacles, including receptacles observed and deemed to be arc-fault circuit interrupter (AFCI)-protected using the AFCI test button, where possible;

- all ground-fault circuit interrupter receptacles and circuit breakers observed and deemed to be GFCIs using a GFCI tester, where possible; (excludes GFCI operation where resets are required) and

- smoke and carbon-monoxide detectors.

- Building Supporters high performance standards include opening electrical panels, but only at the sole discretion of the inspector. The inspector reserves the right to decline opening any panel, for any reason; inspection does not guarantee panels are to be opened.

- The inspector shall describe:

- the main service disconnect’s amperage rating, if labeled; and

- the type of wiring observed; including any immediate signs of visual-only aluminum wiring remediation.

III. The inspector shall report as in need of correction:

- deficiencies in the integrity of the service-entrance conductors’ insulation, drip loop, and vertical clearances from grade and roofs;

- any unused circuit-breaker panel opening that was not filled;

- the presence of solid conductor aluminum branch-circuit wiring, if readily visible;

- any tested receptacle in which power was not present, polarity was incorrect, the cover was not in place, the GFCI devices were not properly installed or did not operate properly, evidence of arcing or excessive heat, and where the receptacle was not grounded or was not secured to the wall; and

- the absence of smoke detectors.

- The inspector is not required to:

- insert any tool, probe or device into the main panelboard, sub-panels, distribution panelboards, or electrical fixtures.

- operate electrical systems that are shut down.

- remove panelboard cabinet covers or dead fronts.

- operate or re-set over-current protection devices or overload devices.

- operate smoke or carbon-monoxide detectors.

- measure or determine the amperage or voltage of the main service equipment, if not visibly labeled.

- inspect the fire and alarm system or components. *Building Supporters High-Performance standards include a report of missing smoke detectors.

- inspect the ancillary wiring or remote-control devices.

- activate any electrical systems or branch circuits that are not energized.

- inspect low-voltage systems, electrical de-icing tapes, swimming pool wiring, or any time-controlled devices.

- verify the service ground.

- inspect private or emergency electrical supply sources, including, but not limited to: generators, windmills, photovoltaic solar collectors, or battery or electrical storage facility.

- Load test any receptacle or test any GFCI devices

- inspect spark or lightning arrestors.

- inspect or test de-icing equipment.

- conduct voltage-drop calculations.

- determine the accuracy of labeling.

- inspect exterior lighting. In particular, home inspectors only inspect exterior lighting directly attached to the house. Landscaping lights, driveway lights, or any lights not directly attached to the house are excluded. We recommend asking the seller to demonstrate proper operation.

3.8. Fireplace

The inspection of masonry chimneys, factory-built chimneys, and free-standing, wood-burning fireplaces is purely visual. It is not a substitute for a Phase 1 inspection. NFPA-style inspections are beyond the scope of a generalist home inspection and should not to be confused with a Level 1, Level 2, or Level 3 inspection, which are conducted by licensed specialists who have knowledge of fire-codes and chimney specifications, and involve dismantling components and/or investigations with specialized equipment, such as video-cameras. * Building Supporters offers Level 1 and 2 chimney inspections as auxiliary service as an add-on service, for an additional fee.

- The inspector shall inspect:

- readily accessible and visible portions of the fireplaces and chimneys;

- lintels above the fireplace openings;

- damper doors by opening and closing them, if readily accessible and manually operable; and

- cleanout doors and frames.

- The inspector shall describe:

- the type of fireplace;

III. The inspector shall report as in need of correction:

- evidence of joint separation, damage or deterioration of the hearth, hearth extension or chambers;

- manually operated dampers that did not open and close;

- the lack of a smoke detector in the same room as the fireplace;

- the lack of a carbon-monoxide detector in the same room as the fireplace; and cleanouts not made of metal, pre-cast cement, or other non-combustible material.

- The inspector is not required to:

- inspect the flue or vent system.

- inspect the interior of chimneys or flues, fire doors or screens, seals or gaskets, or mantels.

- determine the need for a chimney sweep.

- operate gas fireplace inserts.

- light pilot flames.

- determine the appropriateness of any installation.

- inspect automatic fuel-fed devices.

- inspect combustion and/or make-up air devices.

- inspect heat-distribution assists, whether gravity-controlled or fan-assisted.

- ignite or extinguish fires.

- determine the adequacy of drafts or draft characteristics.

- move fireplace inserts, stoves or firebox contents.

- perform a smoke test.

- dismantle or remove any component.

- perform a National Fire Protection Association (NFPA)-style inspection.

- perform a Phase I fireplace and chimney inspection.

3.9. Attic, Insulation, Ventilation

Attics should be well-insulated and, in most cases, well-ventilated. However, the quality of each will vary from region to region, and has become more stringent with the passage of time. The specific identification of insulating materials is beyond the scope of an inspection, but consumers need to be aware than some old insulating materials may contain asbestos and other potential carcinogens or environmental contaminants.

- The inspector shall inspect:

- insulation in unfinished spaces, including attics, crawlspaces and foundation areas;

- ventilation of unfinished spaces, including attics, crawlspaces and foundation areas; and

- mechanical exhaust systems in the kitchen, bathrooms and laundry area.

- The inspector shall describe:

- the type of insulation observed; and

- the approximate average depth of insulation observed at the unfinished attic floor area or roof structure.

III. The inspector shall report as in need of correction:

- the general absence of insulation or ventilation in unfinished spaces.

- The inspector is not required to:

- enter the attic or any unfinished spaces that are not readily accessible, or where entry could cause damage or, in the inspector’s opinion, pose a safety hazard.

- move, touch or disturb insulation.

- move, touch or disturb vapor retarders.

- break or otherwise damage the surface finish or weather seal on or around access panels or covers.

- identify the composition or R-value of insulation material. * Building Supporters offers material laboratory testing, as an auxiliary service for an additional fee.

- activate thermostatically operated fans.

- determine the types of materials used in insulation or wrapping of pipes, ducts, jackets, boilers or wiring. * Building Supporters offers material laboratory testing, as an auxiliary service for an additional fee.

- determine the adequacy of ventilation.

3.10. Doors, Windows & Interior

- The inspector shall inspect:

- a representative number of doors and windows by opening and closing them;

- floors, walls and ceilings;

- stairs, steps, landings, stairways and ramps;

- railings, guards and handrails; and

- garage vehicle doors and the operation of garage vehicle door openers, using normal operating controls.

- Inspector shall describe:

- a garage vehicle door as manually-operated or installed with a garage door opener.

III. Inspector shall report as in need of correction:

- improper spacing between intermediate balusters, spindles and rails for steps, stairways, guards and railings;

- photo-electric safety sensors that did not operate properly; and

- any window that was obviously fogged or displayed other evidence of broken seals.

- The inspector is not required to:

- inspect paint, wallpaper, window treatments or finish treatments.

- inspect floor coverings or carpeting.

- inspect central vacuum systems.

- inspect for safety glazing.

- inspect security systems or components.

- evaluate the fastening of islands, countertops, cabinets, sink tops or fixtures.

- move furniture, stored items, or any coverings, such as carpets or rugs, in order to inspect the concealed floor structure.

- move suspended-ceiling tiles.

- inspect or move any household appliances.

- inspect or operate equipment housed in the garage, except as otherwise noted.

- verify or certify the proper operation of any pressure-activated auto-reverse or related safety feature of a garage door.

- operate or evaluate any security bar release and opening mechanisms, whether interior or exterior, including their compliance with local, state or federal standards.

- operate any system, appliance or component that requires the use of special keys, codes, combinations or devices.

- operate or evaluate self-cleaning oven cycles, tilt guards/latches, or signal lights.

- inspect microwave ovens or test leakage from microwave ovens. * Building Supporters High-Performance standards include a general microwave oven leakage test.

- operate or examine any sauna, steam-generating equipment, kiln, toaster, ice maker, coffee maker, can opener, bread warmer, blender, instant hot-water dispenser, or other small, ancillary appliances or devices.

- inspect elevators.

- inspect remote controls.

- inspect appliances.

- inspect items not permanently installed.

- discover firewall compromises.

- inspect pools, spas or fountains. * Building Supporters offers an auxiliary service as an add-on service, for an additional fee.

- determine the adequacy of whirlpool or spa jets, water force, or bubble effects.

- determine the structural integrity or leakage of pools or spas. * Building Supporters offers general leak detection as an add-on auxiliary service, for an additional fee.

The following sections are added for clarification by Building Supporters and may not be part of InterNACHI SOP’s:

LIVING AREAS

Cracks around windows and doors confirm movement, commonly due to wood shrinkage, settling, or seismic activity, and can reappear, and particularly if they are not repaired well. Such cracks may only have a cosmetic significance but can become the subject of disputes, and are best evaluated by specialists. Similarly, there are a number of environmental pollutants that could be present but not identified during an inspection, and particularly if a residence was built prior to 1978, but which could be revealed by a specialist. In addition, there are a host of contaminants, such as that from moisture penetrating carpet-covered cracks in floor slabs, as well as odors from household pets and cigarette smoke that can permeate walls, carpets, heating and air conditioning ducts, and other porous surfaces, and which can be difficult to eradicate. However, in as much as the sense of smell adjusts rapidly, and the sensitivity to such odors is not uniform, consumers are advised to make this determination for themselves, and particularly if they or a family member suffers from allergies or asthma.

The inspector IS required to report on:

- The visible condition of doors, floors, walls, ceilings, windows, closets, and attached cabinetry.

- The condition of stairs, handrails, and guardrails.

- A representative sampling of windows and doors and their operation.

The inspector IS NOT required to report on:

- Cosmetic imperfections or the wear-and-tear associated with time and use, pets, or lack of care.

- Any area concealed or inaccessible due to rugs, carpets, furniture, tile, or similar items.

- Quality of workmanship.

- Curtains, window treatments, or wall hangings.

- Computerized systems or controls.

- Intercoms, audio or media systems.

- Elevators, dumb-waiters, or other means of mechanical transport.

- Low-voltage systems.

- Security systems.

- The possibility of moisture intrusion.

- Indoor air quality, unless licensed and authorized to do so.

- Systems that are designed to mitigate environmental contaminants.

- Adequacy or quality of locks.

SLEEPING ROOMS

The threat of fire and carbon monoxide poisoning (the silent killer) is greatest when people are asleep. Unfortunately however, several proven methods of combating these threats are not mandated. For instance, arc-fault interrupters and hardwired smoke detectors have only recently been mandated for new construction, and carbon monoxide detectors are still not required in most jurisdictions. And although InterNACHI standards do not supersede local, regional, and national standards, consumers are urged to take whatever means necessary to safeguard themselves, including having these important devices installed and practicing an emergency evacuation of sleeping quarters, and particularly with children and the elderly.

The inspector IS required to report on:

- The visible condition of doors, floors, walls, ceilings, windows, and closets.

- The adequacy of light and ventilation.

- The adequacy for an emergency exit and egress.

- The adequate separation from a garage.

- The presence or absence of smoke detectors.

- The condition of doors, floors, walls, ceilings, and windows.

The inspector IS NOT required to report on:

- Cosmetic imperfections or the wear-and-tear associated with time and use.

- Sleeping quarters that fail to meet conditions 1 through 4, above.

- The functionality of smoke and carbon-monoxide detectors.

- Cosmetic imperfections or the wear-and-tear associated with time and usage.

KITCHEN

Kitchen appliances are tested for their functionality, and not for their performance or the variety of their settings and cycles, and only built-in appliances are tested, which does not include refrigerators. However, any appliance older than ten years is likely to exhibit decreased efficiency. Also, many older gas and electric ranges are not anchored and can be tipped, by a child climbing on an open oven door, for instance, and should therefore be confirmed to be secure and otherwise child-safe.

The inspector IS required to report on:

- The condition of the floor, walls, ceiling, windows, and doors.

- The functionality of built-in appliances, unless disclaimed.

- Faucets and drains and report on their functional flow and draw.

- The ground fault capacity of countertop outlets.

- Confirm that island countertops are secure.

- Building Supporters high performance standards include range anti-tip bracket installation.

The inspector IS NOT required to report on:

- Cosmetic imperfections or the wear-and-tear associated with time and use.

- Curtains, window treatments, or wall hangings.

- Free-standing appliances.

- Countertop or cabinetry lights, which are not built-in.

- Dumb-waiters or similar mechanical devices.

- The future performance of any appliance.

- Countertop appliances.

BATHROOMS

A significant amount of accidents occur in bathrooms, usually due to wet and slippery floors, and less often because of hazardous conditions involving water and electricity. However, safety is a truly personal responsibility that consumers should accept not only for themselves but for dependant family members, such as children and the elderly. It is important, therefore, to follow all recommendations for safety upgrades.

The inspector IS required to report on:

- The condition of the floor, walls, ceiling, windows, and doors.

- Faucets and the drains in sinks, tubs, hydro-spas and showers.

- Toilets and bidets, but not their shut-off valves.

- The ground fault protection of counter top outlets.

- The ground fault protection of hydro-spas.

- The presence of impact glazing where appropriate.

The inspector IS NOT required to report on:

- Flood-test showers or guarantee the integrity of shower pans.

- The condition or effectiveness of the over-flow drains at tubs, sinks, or drain pans (water heater, washer, AC units, etc.).

- Cosmetic deficiencies, mineral stains on enclosures, fixtures, etc.

- Temperature regulating devices.

- Steam showers and their components.

- Saunas and their components.

LAUNDRY FACILITIES

Dryer vents have been responsible for many house fires, injuries, and even deaths. The best dryer vents are smooth-walled and rigid and extend no more than six feet to an exterior location. Water poses less of a threat, but washing machines should be installed over drain-pans plumbed to the exterior, and washing machine hoses should be a resilient braided stainless steel, as opposed to the older rubber type, and this is particularly important in locations where a leak or overflow could cause damage.

The inspector IS required to report on:

- The condition of the floor, walls, ceiling, windows, doors, and cabinets.

- The provision for hot and cold water.

- Type of fuel for a dryer.

- a gas dryer’s capacity to vent to the exterior or to an approved location.

- Building Supporters High-Performance standards include checking readily-accessible dryer vents for exterior-only, immediate obstructions; excludes scoping.

The inspector IS NOT required to report on:

- Cosmetic imperfections or the wear-and-tear associated with time and use.

- The functionality of the washer and dryer.

- Life-expectancy of washer and dryer.

GARAGE

Many fires begin in attached garages and spread inside residences, due in large measure to the presence of volatile fluids and the flash-ignition of vapors. For these reasons, attached garages should have ventilation ports, firewalls, self-closing and fire-rated house entry doors, and ground fault protected outlets. On a different subject, moisture intrusion is common in garages. This typically appears as efflorescence (salt crystal formations) on slabs and the short stem walls surrounding slabs, which is activated by moisture. However, inasmuch as the majority of residential garages are built on-grade and are subject to moisture intrusion, this is be anticipated. It is essential, therefore, to monitor a garage during the rainy season and to keep storage items raised above the slab floor.

The inspector IS required to report on:

- The condition of the slab, walls, windows, etc.

- The generic type of garage door(s).

- Hardware, and confirm that springs have safety cables.

- Garage door openers and confirm their auto-reversing capacity.

- presence of plaster firewalls in attached garages.

- House entry doors and their fire-rating and self-closing capacity.

- Confirm that wall outlets are ground fault protected.

The inspector IS NOT required to report on:

- Areas that are obstructed, by vehicles, or storage items, etc.

- The adequate accommodation for all vehicles.

- Storage facilities added after the initial construction.

- Common curing cracks in slabs, or salt-crystal formations [efflorescence].

- Life-expectancy of garage door opener or garage door components.

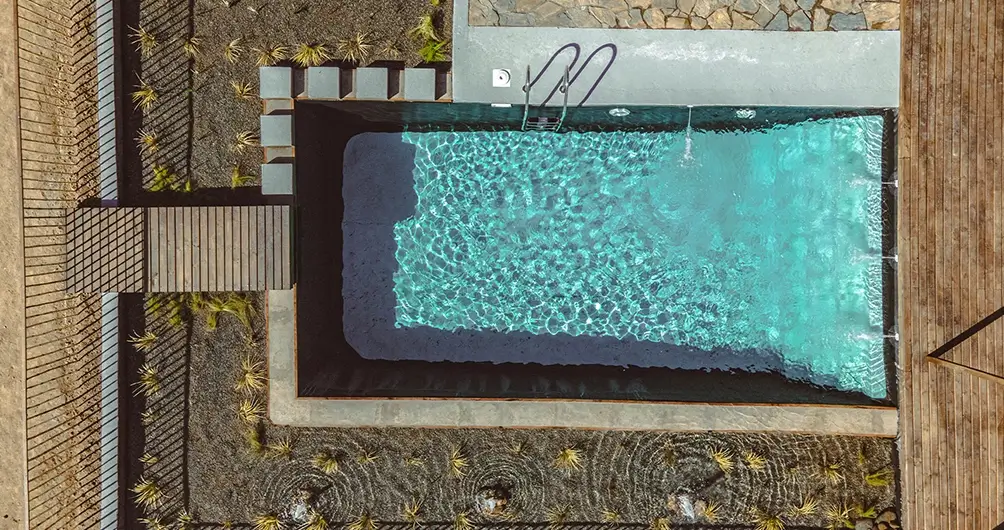

POOLS & SPA [AN AUXILIARY SERVICE]

Pools and spas do leak, but this may be impossible to confirm without the use of specialized equipment. However, it could become apparent from secondary evidence during the inspection, which is purely visual. Regardless, the owner or the occupant of a property would be aware that the water level drops regularly and must be topped off, and this should be disclosed. Unusually high water bills could reveal this, but only a pressure test of the pipes, a dye test of cracks, or a geo-phone test of specific areas would confirm it, which is beyond InterNACHI standards and disclaimed as a function of the inspection. * Building Supporters offers an auxiliary service as an add-on service which includes leak detection testing, for an additional fee.

2.1. Limitations:

- Inspectors are not required to inspect or perform any action not explicitly detailed in these Standards.

- Inspectors are not required to come into direct contact with pool or spa water.

- Inspectors are not required to enter the pool or spa.

- Inspectors are not required to drain a pool or spa in order to inspect it.

- A residential pool and spa inspection is not technically exhaustive.

- A residential pool and spa inspection will not identify concealed or latent defects.

- A residential pool and spa inspection will not deal with aesthetic concerns, or what could be deemed matters of taste, cosmetic defects, etc.

- A residential pool and spa inspection does not include items not permanently installed.

2.2. Exclusions:

- The inspector is not required to determine:

- the condition of any component or system that is not readily accessible.

- the service life expectancy of any component or system.

- the size, capacity, performance or efficiency of any component or system.

- the cause or reason of any condition.

- the cause for the need of correction, repair or replacement of any system or component.

- future conditions.

- compliance with codes or regulations.

- the presence of evidence of rodents, birds, bats, animals, insects, or other pests.

- the presence of mold, mildew or fungus.

- the existence of environmental hazards.

- the existence of electromagnetic fields.

- any hazardous waste conditions.

- any manufacturers’ recalls or conformance with manufacturer installation, or any information included for consumer protection purposes.

- correction, replacement or repair cost estimates.

- estimates of the cost to operate any given system.

- The inspector is not required to operate:

- any system that is shut down.

- any system that does not function properly.

- any system that does not turn on with the use of normal operating controls.

- any shut-off valves or manual stop valves.

- any electrical disconnect or over-current protection devices.

- any alarm systems.

III. The inspector is not required to:

- perform any action that contradictions any laws or regulations.

- activate any component of the pool or spa.

- move any personal items or other obstructions, such as, but not limited to: furniture, equipment or debris.

- dismantle, open or uncover any system or component.

- enter or access any area that may, in the inspector’s opinion, be unsafe.

- do anything that may, in the inspector’s opinion, be unsafe or dangerous to him/herself or others, or damage property, such as, but not limited to negotiating with pets.

- inspect decorative items.

- offer guarantees or warranties.

- offer or perform any engineering services.

- offer or perform any trade or professional service other than a pool and spa inspection.

- research the history of the property, or report on its potential for alteration, modification, extendibility or suitability for a specific or proposed use for occupancy.

- determine the age of construction or installation of any system, structure or component of a unit, or differentiate between original construction and subsequent additions, improvements, renovations or replacements.

- determine the insurability of the property.

- Residential Pool and Spa Inspection

- The inspector shall inspect from ground level:

- the plumbing;

- the filters;

- the lights;

- any adjoining structure as it relates to the pool or spa;

- the valves;

- the solar heating system;

- the pumps and motors;

- the electrical system;

- the filtration system;

- the pool heater; and

- the safety barriers.

- The inspector shall describe:

- the type of swimming pool or spa;

- details impacting the inspector’s ability to inspect the unit, including water clarity;

- the condition of visible components or systems present in the unit;

- the type of drain installed;

- any readily accessible component with functional or material defects;

- the type of filtration system; and

- the types of safety barriers.

III. The inspector shall report as in need of correction:

- observed indications of active pool or spa shell leaks;

- damaged water line tiles;

- damaged or faulty drain covers, pumps; heaters or filter housings;

- inadequate drainage;

- improper settlement of pool deck; and

- any visibly unsafe or improper pool equipment, electrical connections, or bonding connections.

IIII. Additional exclusions:

• Pool body and decorative components such as tile, paint, and special coatings. • All underground piping and electrical, and leak detection of non-visible plumbing. • Chemical and water treatment systems, including the chemical conditions of the water in the pool/spa. • Sizing, adequacy and projections of life expectancy or future performance of any equipment, system, structure or component. • Determining compliance with installation guidelines, regulations, covenants, or other restrictions, including, local interpretations thereof, or the issuance of permits. • Adequacy of solar panels or the mounting thereof. • All Diving boards and/or slides. • Programming computerized control systems. • Manual operation of valves.