InterNACHI promotes these Standards in collaboration with its sister organization, the Certified Commercial Property Inspectors Association (CCPIA). InterNACHI is a non-profit corporation dedicated to advancing the cause of consumers and its membership through education. The purchase of a property is typically the most significant investment that consumers make, and that investment needs to be protected. As a consequence, thousands of inspections are conducted daily that result in the production of legal documents, such as inspection reports, contracts, and a variety of agreements, and it is essential therefore that consumers understand what a property inspection does include and what it does not include.

InterNACHI property inspectors are professional individuals who in exchange for a fee agree to accept the responsibility of evaluating and reporting on the interrelated conditions and components of a property with a “degree of care that a reasonably prudent home inspector would exercise,” Inspection is defined as “a non-invasive physical examination, performed for a fee in connection with the transfer … of a property,” undertaken in an attempt to identify “material defects” that could significantly “affect the value, desirability, habitability, or safety of the dwelling.” However, even this definition is subject to interpretation and debate, and what constitutes a InterNACHI inspection needs to be explained and clearly understood, for practical, ethical, and legal purposes. To borrow an example from medicine, an InterNACHI property inspector is similar to a general practitioner, who has learned a lot about medicine and the human body but has not specialized in any one particular discipline. Similarly, InterNACHI inspectors know a lot about the building trades, such as roofing, plumbing, heating, air-conditioning, and electrical, but they are not licensed specialists. In fact, like general practitioners, it is their responsibility to defer to specialists. For this reason, InterNACHI property inspections are limited in their scope.

InterNACHI property inspections are “non-invasive” and essentially visual and, as stated, are intended to alert consumers in a “written report” to “material defects” that exist at the time of an inspection, defects that could significantly affect the value of a property or pose a threat to health and safety. A property inspection is not technically exhaustive, and is not intended to be, and will not reveal every defect and deficiency. For instance, a property inspection does not include research to establish code-compliance, recall notices, or prior reports. Therefore, an inspection report should not be regarded as a substitute for the seller’s transfer disclosure statement (TDS), which the sellers are required to provide by the Business and Professions Code, or as an insurance policy, warranty, or guaranty. Some defects may be latent, and/or become apparent at a later point in time, which is why inspections have been sensibly characterized as snapshots in time. And it is essential that consumers understand this and, thereby, have reasonable expectations. However, the terms “non-invasive” and “visual” also need further explanation. For example, an inspector may remove the interior cover from an electrical panel, which could be said to be invasive, and inserting an electrical tester into a wall outlet could be construed as being more than a visual examination. Regardless, most inspectors remove cover panels and use a variety of specialized instruments in the service of their clients, but the use of such instruments does not distinguish them as specialists; only a licensing authority can legitimately confer that distinction. InterNACHI inspectors adhere to clearly defined standards and state laws, and to this extent InterNACHI standards are intended to be legally binding.

PURPOSE AND SCOPE

1.1.

1.1 The purpose of this document is to define best practices and to

establish a reasonable approach for the performance of an

inspection of a commercial property.

A commercial inspection is a non-invasive, visual examination of the accessible areas of a residential property (as delineated below), performed for a fee, which is designed to identify defects within specific systems and components defined by these Standards that are both observed and deemed material by the inspector. The scope of work may be modified by the Client and Inspector prior to the inspection process.

- The commercial inspection is based on the observations made on the date of the inspection, and not a prediction of future conditions.

- The commercial inspection will not reveal every issue that exists or ever could exist, but only those material defects observed on the date of the inspection.

1.2.

A material defect is a specific issue with a system or component of a residential property that may have a significant, adverse impact on the value of the property, or that poses an unreasonable risk to people. The fact that a system or component is near, at or beyond the end of its normal useful life is not, in itself, a material defect.

1.3.

A commercial inspection report shall identify, in written format, defects within specific systems and components defined by these Standards that are both observed and deemed material by the inspector. Inspection reports may include additional comments and recommendations. Inspectors will report on required items only when a defect is found.

LIMITATIONS, EXCEPTIONS & EXCLUSIONS

2.1. Limitations:

- An inspection is not technically exhaustive. This means that we do not diagnose the condition of components in a house beyond their function with normal operator controls. If a component does not work, further evaluation and/or repair will be noted in the report.

- An inspection does not guarantee a property will be free of defects, or that all defects will be reported/observed within a limited time frame and scope. There is no insurance nor coverage of any kind of repairs.

- An inspection will not identify concealed or latent defects. These are defects that are not apparent on the day of the inspection, or those defects that manifest after the inspection. An example is a furnace that works on the day of inspection, but fails after the inspection. Another example is a drain line that flows when the inspector runs clear water, but gets clogged with the use of toilet paper, soap, food items, etc.

- An inspection will not deal with aesthetic concerns or what could be deemed matters of taste, cosmetic defects, etc. Examples of excluded items includes paint, stains on flooring material, worn finishes on cabinets, doors, or decorator items such as curtains, curtain rods, blinds, etc.

- An inspection will not determine the suitability of the property for any use.

- An inspection does not determine the market value of the property or its marketability.

- An inspection does not determine the insurability of the property.

- An inspection does not determine the advisability or inadvisability of the purchase of the inspected property.

- An inspection does not determine the life expectancy of the property or any components or systems therein. Everything in a house can wear out. This includes appliances, HVAC equipment, roofing material, faucets and other plumbing fixtures, door locks and hardware, flooring, window hardware, etc. Just like an older car, parts wear out and a home inspection is not intended to determine the life remaining.

- An inspection does not include items not permanently installed. Examples include refrigerators, clothes washing and drying equipment, electrical equipment attached to a receptacle (timers, TV’s, water feature pumps, windows AC units, room heaters). * Building Supporters High-Performance standards include inspection and recall check (when data is available) including: Refrigerators, clothes washing and drying equipment, dishwashers, and trash compactors.

- These Standards of Practice apply only to properties with four or fewer residential units.

2.2.Exclusions:

I. The inspector is not required to determine:

- Property boundary lines or encroachments.

- The condition of any component or system that is not readily accessible.

- The service life expectancy of any component or system.

- The size, capacity, BTU, performance or efficiency of any component or system. We rely on the builder having installed items according to codes in place at the time of construction. Inspectors do not calculate capacities or efficiency of any items such as HVAC equipment, pool heating and pumping equipment, solar (heating or PV).

- The cause or reason of any condition.

- The cause for the need of correction, repair or replacement of any system or component.

- Future conditions.

- Compliance with codes or regulations. Due to changing building codes on a nearly annual basis, it is impossible for a home inspector to know the exact codes in place at the time of construction. It is not reasonable to hold an older home to today’s building standards. While there are obvious right and wrong ways of installing items or building homes, we specifically do not cite codes within the scope of a home inspection.

- The presence of evidence of rodents, birds, animals, insects, or other pests.

- The presence of mold, mildew or fungus. * Building Supporters high-performance standards include a visual mold assessment. Building Supporters also offers an auxiliary mold testing service as an add-on service, for an additional fee.

- The presence of airborne hazards, including radon. Colorado has a high occurrence of Radon, and * Building Supporters therefore offers an auxiliary radon testing service as an add-on service, for an additional fee.

- The air quality.* Building Supporters offers air sampling and testing as an add-on service, for an additional fee.

- The existence of environmental hazards, including lead paint, asbestos or toxic drywall. * Building Supporters offers material sampling and testing as an add-on service, for an additional fee.

- The existence of electromagnetic fields.

- Any hazardous waste conditions.

- Any manufacturers’ recalls or conformance with manufacturer installation, or any information included for consumer protection purposes. * Building Supporters High-Performance standards include a recall check (when data is available) for: HVAC equipment, hot water heaters, refrigerators, clothes washing and drying equipment, dishwashers, and trash compactors.

- Acoustical properties.

- Correction, replacement or repair cost quotes.

- Quotes of the cost to operate any given system.

II. The inspector is not required to operate:

- any system that is shut down.

- any system that does not function properly.

- or evaluate low-voltage electrical systems such as, but not limited to:

- Phone lines

- Cable lines

- Satellite dishes

- Antennae

- Lights

- Remote controls

- Any system that does not turn on with the use of normal operating controls.

- Any shut-off valves or manual stop valves.

- Any electrical disconnect or over-current protection devices. Home inspectors do not test circuit breakers to determine their effectiveness at times of over-load. A licensed electrician has the specialized tools for this. If you are buying an older home and are concerned about the functionality of breakers, you should have the electrical panel and the breakers tested by a licensed electrician.

- Any alarm systems.

- Moisture meters, gas detectors or similar equipment. * Building Supporters High-Performance standards include a Infrared Thermography Survey and the use of moisture meters based on thermal findings. Gas leak detection is included in Building Supporters High-Performance standards.

III. The inspector is not required to:

- Move any personal items or other obstructions, such as, but not limited to: throw rugs, carpeting, wall coverings, furniture, ceiling tiles, window coverings, equipment, plants, ice, debris, snow, water, dirt, pets, or anything else that might restrict the visual inspection.

- Dismantle, open or uncover any system or component.

- Enter or access any area that may, in the opinion of the inspector, be unsafe. This is solely left to the discretion of the home inspector. An area may be deemed unsafe to enter due to limited clearance, animals, pests, standing water, poor electrical installations, animal waste, laceration hazards, or any other item deemed to be a hazard. This includes yards, side yards, crawl spaces, attics, rooms, garages, or storage rooms.

- Enter crawlspaces or other areas that may be unsafe or not readily accessible.

- Inspect underground items, such as, but not limited to: lawn-irrigation systems, underground storage tanks or other indications of their presence, whether abandoned or actively used.

- Do anything which may, in the inspector’s opinion, be unsafe or dangerous to the inspector or others, or damage property, such as, but not limited to: walking on roof surfaces, climbing ladders, entering attic spaces, or negotiating with pets.

- Inspect decorative items. This includes curtains, blinds, furniture, and hanging or stationary art.

- Inspect common elements or areas in multi-unit housing. If a component is not the property of the seller, it will not be inspected such as the roof of a condominium or townhouse, exterior stairs, pools, railings, stucco, decks, or any common area items.

- Inspect intercoms, speaker systems or security systems.

- Offer guarantees or warranties. * Building Supporters does offer a guarantee. Please use our search box above by typing the word “guarantee” for details.

- Offer or perform any engineering services. This means that we do not calculate the load-bearing ability of any structure or determine any structural components for adequacy. Home inspectors rely on the builder having built the house to code and according to plans in place at the time of construction. If a part of the structure appears inadequate, the inspector will note it in the report for further evaluation. This includes deck structures, floor structures and roof structures.

- Offer or perform any trade or professional service other than general home inspection. * Building Supporters offers an auxiliary building problem solving service as an add-on service, for an additional fee.

- Research the history of the property, or report on its potential for alteration, modification, extendibility or suitability for a specific or proposed use for occupancy. * Building Supporters standard includes a BUILDFAX property history report when data can be found in the searchable database.

- Determine the age of construction or installation of any system, structure or component of a building, or differentiate between original construction and subsequent additions, improvements, renovations or replacements.

- Determine the insurability of a property.

- Perform or offer Phase 1 or environmental audits. * Building Supporters offers an auxiliary service as an add-on service, for an additional fee.

- Inspect any system or component that is not included in these Standards.

STANDARDS OF PRACTICE

4.1 ObjectiveThe objective of an inspection is to provide written communication describing the issues discovered from observations made and research conducted by the inspector, which, in the inspector’s opinion, are likely to be of interest to his/her client, and to enhance the client’s information and knowledge about the commercial property to improve decision-making for buying, selling, maintaining or improving the property.4.2 Who May Perform the InspectionAny portion of the inspection, including the walk-through survey, research and report-generation, may be performed by the inspector, his/her staff, or any consultant hired by the inspector. This Standard recognizes that, for the majority of commercial inspections, the inspector is likely an individual with a general, well-rounded knowledge of commercial properties, and that the inspector or client may want to augment the inspector’s skills with specialty consultants who have particular expertise in certain areas. The decision to hire specialty consultants will, of course, rely on budget and time constraints, as well as the risk-tolerance of the client.

4.3 Varying Levels of Due DiligenceThis Standard is designed as a baseline from which the inspector and client can develop and agree to a scope of work that may deviate from this Standard, depending on budget, time constraints, purpose of the inspection, age of the subject property, and risk-tolerance of the client. The level of due diligence should be set where the cost, in time and money, of acquiring information about the subject property will not likely exceed the value of that information. Therefore, an inspection performed in accordance with this Standard will not be technically exhaustive.4.3.1 Sample Language for Use When Defining the Scope of

Work“The inspection will be performed in accordance with InterNACHI-CCPIA ComSOP, except that…”4.3.2 Representative ObservationsIn recognizing that the client likely has the goal of acquiring information about the subject property at a cost, in time and money, that does not exceed the value of that information, representative observations are not just permitted by this Standard, but recommended, as well.4.4 UncertaintyThe client should understand that no inspection report is completely accurate. A report is only the written communication of the observations made and research conducted by the inspector. The report contains those items which, in the inspector’s opinion, are likely to be of interest to his/her client.4.5 SubjectivityThe client should understand that the inspection report is, to a large degree, the subjective opinions of the inspector based on his/her observations and research within the limits of access, time and budget, and without the aid of special equipment or meters, and without dismantling, probing, testing or troubleshooting, and without detailed knowledge of the commercial property, its components or its systems. The inspection report is not much more than a subjective professional opinion.4.6 Not an Architectural or Engineering ServiceAn inspector performing a commercial inspection in accordance with this Standard is not practicing architecture or engineering.4.7 Not a Warranty, Guarantee or Insurance PolicyThe inspection is not a warranty, and the inspection report is merely the written communication of the inspector’s subjective opinion on the condition of the subject property.

5.1 ObjectiveThe objective of research, including the review of documents and the performing of interviews, is to augment the information obtained during the walk-through survey and to provide supporting documentation to the inspection report.5.2 Document ProcurementIt is the client’s responsibility to obtain copies of all documents and provide them for the inspector. These documents are most often obtained from the seller or from local government offices. The inspector is not responsible for gathering or paying for copies of appropriate documents to be reviewed unless these tasks are specifically assigned to the inspector in the Scope of Work Agreement.5.3 Documents to Be Reviewed and Included in the Inspection ReportThe inspector should review all documents provided by the client and owner. The inspector should also make an inquiry and review of any other documents that can be reasonably procured on-site or from the building owner or manager, such as Certificates of Occupancy, building code violation notices, repair invoices, and warranties. The inspector is not required to uncover and review information that is not provided or cannot be reasonably ascertained or acquired on-site. Copies of documents that the inspector believes may be of interest to the client and copies of documents that support the inspector’s opinions should be included in the inspection report.5.3.1 Examples of documents the inspector may want to request for review:

- fire-detection test and maintenance records;

6.1 ObjectiveThe objective of the walk-through survey is to allow the inspector to visually observe the subject property, gather information, and note items of interest.6.2 Access ResponsibilityIt is the client’s responsibility to arrange for the inspector to receive timely access to the subject property for the walk-through survey portion of the inspection, as well as access to all documents and interviewees needed for the research portion of the inspection. This includes access to all documents, information and previously generated reports in the client’s possession. The inspector is not responsible for obtaining, reviewing or providing information, should the source withhold, impede or delay access. Anything that hinders the inspector’s access should be noted in the report.6.3 RevisitsIt is expected that the inspector will perform only one walk-through survey per inspection report. However, it may be necessary for the inspector to revisit certain areas of the subject building after performing the research portion of the inspection.6.4 Inspector SafetyIt is the responsibility of the inspector to perform the walk-through survey safely.6.5 Observations6.5.1 RoofI. The inspector should inspect from ground level, eaves or rooftop (if a rooftop access door exists):

A. the roof covering;B. for the presence of exposed membrane;C. slopes;

D. for evidence of significant ponding;

E. the gutters;

F. the downspouts;

G. the vents, flashings, skylights, chimney and other roof penetrations;

H. the general structure of the roof from the readily accessible panels, doors or stairs; andI. for the need for repairs.II. The inspector is not required to:

A. walk on any pitched roof surface.

B. predict service-life expectancy.

C. inspect underground downspout diverter drainage pipes.

D. remove snow, ice, debris or other conditions that prohibit the observation of the roof surfaces.E. move insulation.

F. inspect antennae, lightning arresters, de-icing equipment or similar attachments.G. walk on any roof areas that appear, in the opinion of the inspector, to be unsafe.H. walk on any roof areas if it might, in the opinion of the inspector, cause damage.I. perform a water test.J. warrant or certify the roof.

K. walk on any roofs that lack rooftop access doors.6.5.2 Exterior

I. The inspector should inspect:

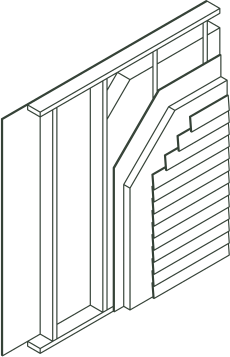

A. the siding, flashing and trim;

B. all exterior doors, decks, stoops, steps, stairs, porches, railings, eaves, soffits and fasciae;C. and report as in need of repair any safety issues regarding intermediate balusters, spindles or rails for steps, stairways, balconies and railings;D. a representative number of windows;

E. the vegetation, surface drainage, and retaining walls when these are likely to adversely affect the structure;F. the exterior for accessibility barriers;G. the storm water drainage system;H. the general topography;I. the parking areas;J. the sidewalks;K. exterior lighting;L. the landscaping;M. and determine that a 3-foot clear space exists around the circumference of fire hydrants;

N. and describe the exterior wall covering.II. The inspector is not required to:

A. inspect or operate screens, storm windows, shutters, awnings, fences, outbuildings or exterior accent lighting.

B. inspect items, including window and door flashings, that are not visible or readily accessible from the ground.

C. inspect geological, geotechnical, hydrological or soil conditions.

D. inspect recreational facilities.

E. inspect seawalls, breakwalls or docks.

F. inspect erosion-control or earth-stabilization measures.

G. inspect for proof of safety-type glass.H. determine the integrity of thermal window seals or damaged glass.

I. inspect underground utilities.

J. inspect underground items.

K. inspect wells or springs.

L. inspect solar systems.

M. inspect swimming pools or spas.

N. inspect septic systems or cesspools.

O. inspect playground equipment.

P. inspect sprinkler systems.

Q. inspect drainfields or dry wells.R. inspect manhole covers.S. operate or evaluate remote-control devices, or test door or gate operators.6.5.3 Wood Decks and BalconiesI. The inspector should inspect:A. with the unaided eye, for deck and balcony members that are noticeably out of level or out of plumb;B. for visible decay;C. for paint failure and buckling;D. for nail pullout (nail pop);E. for fastener rust, iron stain and corrosion;F. and verify that flashing was installed on the deck-side of the ledger board;G. for vertical members (posts) that have exposed end-grains;H. for obvious trip hazards;I. for non-graspable handrails;J. railings for height less than the 36-inch minimum*;K. guardrails and infill for openings that exceed the 4-inch maximum*;L. open-tread stairs for openings that exceed the 4⅜-inch maximum*;M. the triangular area between guardrails and stairways for openings that exceed the 6-inch maximum*;N. built-up and multi-ply beam spans for butt joints;O. for notches in the middle-third of solid-sawn wood spans;P. for large splits longer than the depths of their solid-sawn wood members;Q. for building egresses blocked, covered or hindered by deck construction; andR. for the possibility of wetting from gutters, downspouts or sprinklers.

*See https://www.nachi.org/stairways.htm for formal standards (compliance verification in entirety not required).

II. The inspector is not required to:A. discover insect infestation or damage.B. inspect, determine or test the tightness or adequacy of fasteners.C. determine lumber grade.D. measure moisture content.E. inspect for or determine bending strength.F. inspect for or determine shear stress.G. determine lag screw or bolt shear values.H. calculate loads.I. determine proper spans or inspect for deflections.J. discover decay hidden by paint.K. verify that flashing has been coated to prevent corrosion.L. determine that post-to-footing attachments exist.M. dig below grade or remove soil around posts.N. crawl under any deck with less than 3 feet of headroom, or remove deck skirting to acquire access.O. determine proper footing depth or frostline.P. verify proper footing size.Q. perform pick tests.R. perform or provide any architectural or engineering service.S. use a level or plumb bob.T. use a moisture meter.U. predict service-life expectancy.V. verify compliance with permits, codes or formal standards.W. inspect for disabled persons’ accessibility barriers.X. determine if a deck blocks, covers or hinders septic tank or plumbing access.Y. determine easement-encroachment compliance.6.5.4 Basement, Foundation and CrawlspaceI. The inspector should inspect:

A. the basement;

B. the foundation;

C. the crawlspace;

D. the visible structural components;E. and report on the location of under-floor access openings;

F. and report any present conditions or clear indications of active water penetration observed by the inspector;G. for wood in contact with or near soil;H. and report any general indications of foundation movement that are observed by the inspector, such as, but not limited to: sheetrock cracks, brick cracks, out-of-square door frames, or floor slopes;I. and report on any cutting, notching or boring of framing members that may present a structural or safety concern.II. The inspector is not required to:

A. enter any crawlspaces that are not readily accessible, or where entry could cause damage or pose a hazard to the inspector.

B. move stored items or debris.

C. operate sump pumps.

D. identify size, spacing, span or location, or determine the adequacy of foundation bolting, bracing, joists, joist spans or support systems.

E. perform or provide any engineering or architectural service.

F. report on the adequacy of any structural system or component.6.5.5 Heating and VentilationI. The inspector should inspect:

A. multiple gas meter installations, such as a building with multiple tenant spaces, and verify that each meter is clearly and permanently identified with the respective space supplied;B. the heating systems using normal operating controls, and describe the energy source and heating method;

C. and report as in need of repair heating systems that do not operate;

D. and report if the heating systems are deemed inaccessible;E. and verify that a permanent means of access, with permanent ladders and/or catwalks, are present for equipment and appliances on roofs higher than 16 feet;F. and verify the presence of level service platforms for appliances on roofs with a slope of 25% or greater;G. and verify that luminaire and receptacle outlets are provided at or near the appliance;H. and verify that the system piping appears to be sloped to permit the system to be drained;I. for connectors, tubing and piping that might be installed in a way that exposes them to physical damage;J. wood framing with cutting, notching or boring that might cause a structural or safety issue;K. pipe penetrations in concrete and masonry building elements to verify that they are sleeved;L. exposed gas piping for identification by a yellow label marked “Gas” in black letters occurring at intervals of 5 feet or less;M. and determine if any appliances or equipment with ignition sources are located in public, private, repair or parking garages or fuel-dispensing facilities;N. and verify that fuel-fired appliances are not located in or obtain combustion air from sleeping rooms, bathrooms, storage closets or surgical rooms;O. for the presence of exhaust systems in occupied areas where there is a likelihood of excess heat, odors, fumes, spray, gas, noxious gases or smoke;P. and verify that outdoor air-intake openings are located at least 10 feet away from any hazardous or noxious contaminant sources, such as vents, chimneys, plumbing vents, streets, alleys, parking lots or loading docks;Q. outdoor exhaust outlets for the likelihood that they may cause a public nuisance or fire hazard due to smoke, grease, gases, vapors or odors;R. for the potential of flooding or evidence of past flooding that could cause mold in ductwork or plenums; andS. condensate drains.II. The inspector is not required to:

A. inspect or evaluate interiors of flues or chimneys, fire chambers, heat exchangers, humidifiers, dehumidifiers, electronic air filters, solar heating systems, fuel tanks, safety devices, pressure gauges, or control mechanisms.

B. determine the uniformity, temperature, flow, balance, distribution, size, capacity, BTU, or supply adequacy of the heating system.

C. light or ignite pilot flames.

D. activate heating, heat pump systems, or other heating systems when ambient temperatures or other circumstances are not conducive to safe operation or may damage the equipment.

E. over-ride electronic thermostats.

F. evaluate fuel quality.G. verify thermostat calibration, heat anticipation or automatic setbacks, timers, programs or clocks.H. inspect tenant-owned or tenant-maintained heating equipment.I. determine ventilation rates.J. perform capture and containment tests.K. test for mold.6.5.6 Cooling

I. The inspector should inspect:

A. multiple air-conditioning compressor installations, such as a building with multiple tenant spaces, and verify that each compressor is clearly and permanently identified with the respective space supplied;B. the central cooling equipment using normal operating controls;C. and verify that luminaire and receptacle outlets are provided at or near the appliance;D. and verify that a permanent means of access, with permanent ladders and/or catwalks, are present for equipment and appliances on roofs higher than 16 feet;E. and verify the presence of level service platforms for appliances on roofs with a slope of 25% or greater;F. wood framing with cutting, notching or boring that might cause a structural or safety issue;G. pipe penetrations in concrete and masonry building elements to verify that they are sleeved;H. piping support;I. for connectors, tubing and piping that might be installed in a way that exposes them to physical damage;J. for the potential of flooding or evidence of past flooding that could cause mold in ductwork and plenums; andK. condensate drains.II. The inspector is not required to:

A. inspect or test compressors, condensers, vessels, evaporators, safety devices, pressure gauges, or control mechanisms.B. determine the uniformity, temperature, flow, balance, distribution, size, capacity, BTU, or supply adequacy of the cooling system.

C. inspect window units, through-wall units, or electronic air filters.

D. operate equipment or systems if exterior temperature is below 60° Fahrenheit, or when other circumstances are not conducive to safe operation or may damage the equipment.

E. inspect or determine thermostat calibration, cooling anticipation, or automatic setbacks or clocks.

F. examine electrical current, coolant fluids or gases, or coolant leakage.G. inspect tenant-owned or tenant-maintained cooling equipment.H. test for mold.6.5.7 Plumbing

I. The inspector should inspect:

A. and verify the presence of and identify the location of the main water shut-off valve to each building;B. and verify the presence of a back-flow prevention device if, in the inspector’s opinion, a cross-connection could occur between the water-distribution system and non-potable water or private source;

C. the water-heating equipment, including combustion air, venting, connections, energy-source supply systems, and seismic bracing, and verify the presence or absence of temperature-/pressure-relief valves and/or Watts 210 valves;

D. and flush a representative number of toilets;

E. and water-test a representative number of sinks, tubs and showers for functional drainage;F. and verify that hinged shower doors open outward from the shower, and have safety glass-conformance stickers or indicators;

G. the interior water supply, including a representative number of fixtures and faucets;

H. the drain, waste and vent systems, including a representative number of fixtures;

I. and describe any visible fuel-storage systems;

J. and test sump pumps with accessible floats;

K. and describe the water supply, drain, waste and main fuel shut-off valves, as well as the location of the water main and main fuel shut-off valves;

L. and determine whether the water supply is public or private;

M. the water supply by viewing the functional flow in several fixtures operated simultaneously, and report any deficiencies as in need of repair;

N. and report as in need of repair deficiencies in installation and identification of hot and cold faucets;

O. and report as in need of repair mechanical drain stops that are missing or do not operate if installed in sinks, lavatories and tubs;

P. and report as in need of repair commodes that have cracks in the ceramic material, are improperly mounted on the floor, leak, or have tank components that do not operate; andQ. piping support.II. The inspector is not required to:

A. determine the adequacy of the size of pipes, supplies, vents, traps or stacks.B. ignite pilot flames.

C. determine the size, temperature, age, life expectancy or adequacy of the water heater.

D. inspect interiors of flues or chimneys, cleanouts, water-softening or filtering systems, dishwashers, interceptors, separators, sump pumps, well pumps or tanks, safety or shut-off valves, whirlpools, swimming pools, floor drains, lawn sprinkler systems or fire sprinkler systems.

E. determine the exact flow rate, volume, pressure, temperature or adequacy of the water supply.F. verify or test anti-scald devices.

G. determine the water quality, potability or reliability of the water supply or source.

H. open sealed plumbing access panels.

I. inspect clothes washing machines or their connections.

J. operate any main, branch or fixture valve.K. test shower pans, tub and shower surrounds, or enclosures for leakage.

L. evaluate compliance with local or state conservation or energy standards, or the proper design or sizing of any water, waste or venting components, fixtures or piping.

M. determine the effectiveness of anti-siphon, back-flow prevention or drain-stop devices.

N. determine whether there are sufficient cleanouts for effective cleaning of drains.

O. evaluate gas, liquid propane or oil-storage tanks.

P. inspect any private sewage waste-disposal system or component within such a system.Q. inspect water-treatment systems or water filters.

R. inspect water-storage tanks, pressure pumps, ejector pumps, or bladder tanks.S. evaluate wait time for hot water at fixtures, or perform testing of any kind on water-heater elements.T. evaluate or determine the adequacy of combustion air.U. test, operate, open or close safety controls, manual stop valves, or temperature- or pressure-relief valves.V. examine ancillary systems or components, such as, but not limited to, those relating to solar water heating or hot-water circulation.W. determine the presence or condition of polybutylene plumbing.6.5.8 Electrical

I. The inspector should inspect:

A. the service drop/lateral;

B. the meter socket enclosures;C. the service-entrance conductors, and report on any noted deterioration of the conductor insulation or cable sheath;D. the means for disconnecting the service main;E. the service-entrance equipment, and report on any noted physical damage, overheating or corrosion;

F. and determine the rating of the service disconnect amperage, if labeled;

G. panelboards and over-current devices, and report on any noted physical damage, overheating, corrosion, or lack of accessibility or working space (minimum 30 inches wide, 36 inches deep, and 78 inches high in front of panel) that would hamper safe operation, maintenance or inspection;H. and report on any unused circuit-breaker panel openings that are not filled;I. and report on absent or poor labeling;

J. the service grounding and bonding;K. a representative number of switches, lighting fixtures and receptacles, including receptacles observed and deemed to be AFCI-protected using the AFCI test button, where possible. Although a visual inspection, the removal of faceplates or other covers or luminaires (fixtures) to identify suspected hazards is permitted;L. and report on any noted missing or damaged faceplates or box covers;M. and report on any noted open junction boxes or open wiring splices;N. and report on any noted switches and receptacles that are painted;O. and test all ground-fault circuit interrupter (GFCI) receptacles and GFCI circuit breakers observed and deemed to be GFCIs using a GFCI tester, where possible;P. and report the presence of solid-conductor aluminum branch-circuit wiring, if readily visible;Q. and report on any tested GFCI receptacles in which power was not present, polarity was incorrect, the cover was not in place, the GFCI devices were not installed properly or did not operate properly, any evidence of arcing or excessive heat, or where the receptacle was not grounded or was not secured to the wall;R. and report the absence of smoke detectors;S. and report on the presence of flexible cords being improperly used as substitutes for the fixed wiring of a structure or running through walls, ceilings, floors, doorways, windows, or under carpets.II. The inspector is not required to:

A. insert any tool, probe or device into the main panelboard, sub-panels, distribution panelboards, or electrical fixtures.

B. operate electrical systems that are shut down.

C. remove panelboard cabinet covers or dead fronts if they are not readily accessible.D. operate over-current protection devices.

E. operate non-accessible smoke detectors.

F. measure or determine the amperage or voltage of the main service equipment, if not visibly labeled.

G. inspect the fire or alarm system and components.

H. inspect the ancillary wiring or remote-control devices.

I. activate any electrical systems or branch circuits that are not energized.

J. operate or reset overload devices.

K. inspect low-voltage systems, electrical de-icing tapes, swimming pool wiring, or any time-controlled devices.

L. verify the service ground.

M. inspect private or emergency electrical supply sources, including, but not limited to: generators, windmills, photovoltaic solar collectors, or the battery- or electrical-storage facility.

N. inspect spark or lightning arrestors.O. inspect or test de-icing equipment.

P. conduct voltage-drop calculations.

Q. determine the accuracy of labeling.R. inspect tenant-owned equipment.S. inspect the condition of or determine the ampacity of extension cords.6.5.9 Fireplaces

I. The inspector should inspect:

A. fireplaces, and open and close the damper doors, if readily accessible and operable;

B. hearth extensions and other permanently installed components;

C. and report as in need of repair deficiencies in the lintel, hearth or material surrounding the fireplace, including clearance from combustible materials.II. The inspector is not required to:

A. inspect the flue or vent system.

B. inspect the interior of chimneys or flues, fire doors or screens, seals or gaskets, or mantels.C. determine the need for a chimney sweep.

D. operate gas fireplace inserts.

E. light pilot flames.

F. inspect automatic fuel-feed devices.

G. inspect combustion and/or make-up air devices.

H. inspect heat-distribution assists, whether gravity-controlled or fan-assisted.

I. ignite or extinguish fires.

J. determine draft characteristics.

K. move fireplace inserts, stoves or firebox contents.

L. determine the adequacy of drafts, perform a smoke test, or dismantle or remove any fireplace component.M. perform an NFPA inspection.N. perform a Phase I fireplace and chimney inspection.O. determine the appropriateness of any installation.6.5.10 Attic Ventilation and Insulation

I. The inspector should inspect:

A. the insulation in unfinished spaces;

B. the ventilation of attic spaces;

C. mechanical ventilation systems;

D. and report on the general absence or lack of insulation.II. The inspector is not required to:

A. enter the attic or any unfinished spaces that are not readily accessible, or where entry could cause damage or pose a safety hazard to the inspector, in his or her opinion.

B. move, touch or disturb insulation.

C. move, touch or disturb vapor retarders.

D. break or otherwise damage the surface finish or weather seal on or around access panels or covers.

E. identify the composition or exact R-value of insulation material.

F. activate thermostatically operated fans.

G. determine the types of materials used in insulation or wrapping of pipes, ducts, jackets, boilers or wiring.H. determine the adequacy of ventilation.6.5.11 Doors, Windows and Interior

I. The inspector should:

A. open and close a representative number of doors and windows;

B. inspect the walls, ceilings, steps, stairways and railings;

C. inspect garage doors and garage door-openers;D. inspect interior steps, stairs and railings;E. inspect all loading docks;F. ride all elevators and escalators;G. and report as in need of repair any windows that are obviously fogged or display other evidence of broken seals.II. The inspector is not required to:

A. inspect paint, wallpaper, window treatments or finish treatments.

B. inspect central-vacuum systems.

C. inspect safety glazing.

D. inspect security systems or components.

E. evaluate the fastening of countertops, cabinets, sink tops or fixtures, or firewall compromises.

F. move furniture, stored items, or any coverings, such as carpets or rugs, in order to inspect the concealed floor structure.

G. move drop-ceiling tiles.

H. inspect or move any appliances.I. inspect or operate equipment housed in the garage, except as otherwise noted.

J. verify or certify safe operation of any auto-reverse or related safety function of a garage door.

K. operate or evaluate any security bar-release and opening mechanisms, whether interior or exterior, including their compliance with local, state or federal standards.

L. operate any system, appliance or component that requires the use of special keys, codes, combinations or devices.

M. operate or evaluate self-cleaning oven cycles, tilt guards/latches, gauges or signal lights.

N. inspect microwave ovens, or test leakage from microwave ovens.

O. operate or examine any sauna, steam-jenny, kiln, toaster, ice maker, coffee maker, can opener, bread warmer, blender, instant hot-water dispenser, or other ancillary devices.P. inspect elevators.

Q. inspect remote controls.

R. inspect appliances.

S. inspect items not permanently installed.

T. examine or operate any above-ground, movable, freestanding, or otherwise non-permanently installed pool/spa, recreational equipment, or self-contained equipment.

U. come into contact with any pool or spa water in order to determine the system’s structure or components.

V. determine the adequacy of a spa’s jet water force or bubble effect.

W. determine the structural integrity or leakage of a pool or spa.X. determine combustibility or flammability.Y. inspect tenant-owned equipment or personal property.6.5.12 Life SafetyI. The inspector should:A. inspect fire access roads and report on any obstructions or overhead wires lower than 13 feet and 6 inches;B. inspect the address or street number to determine whether it is visible from the street, with numbers in contrast to their background;C. inspect to determine whether a 3-foot clear space exists around the circumference of fire hydrants;D. verify that hinged shower doors open outward from the shower and have safety glass-conformance stickers or indicators;E. inspect to determine whether the storage of flammable and combustible materials is orderly, separated from heaters by distance or shielding so that ignition cannot occur, and not stored in exits, boiler rooms, mechanical rooms or electrical equipment rooms;F. inspect to determine whether a “No Smoking” sign is posted in areas where flammable or combustible material is stored, dispensed or used;G. inspect for the presence of fire alarm systems;H. inspect for alarm panel accessibility;I. inspect for the presence of portable extinguishers, and determine whether they are located in conspicuous and readily available locations immediately available for use, and not obstructed or obscured from view;J. inspect to determine whether a portable fire extinguisher is stored within a 30-foot travel distance of commercial-type cooking equipment that uses cooking oil or animal fat;K. inspect to determine whether manual-actuation devices for commercial cooking appliances exist near the means of egress from the cooking area, 42 to 48 inches above the floor and 10 and 20 feet away, and clearly identifying the hazards protected;L. inspect to determine whether the maximum travel distance to a fire extinguisher is 75 feet;M. inspect for the presence of sprinkler systems, and determine if they were ever painted other than at the factory;N. inspect for the presence of emergency lighting systems;O. inspect for exit signs at all exits, and inspect for independent power sources, such as batteries;P. inspect for the presence of directional signs where an exit location is not obvious;Q. inspect for the presence of signs over lockable exit doors stating: “This Door Must Remain Unlocked During Business Hours”;R. inspect for penetrations in any walls or ceilings that separate the exit corridors or stairwells from the rest of the building;S. inspect for fire-separation doors that appear to have been blocked or wedged open, or that do not automatically close and latch;T. inspect exit stairwell handrails;U. inspect for exit trip hazards;V. inspect for the presence of at least two exits to the outside, or one exit that has a maximum travel distance of 75 feet;W. inspect exit doorways to determine whether they are less than 32 inches in clear width;X. inspect to determine whether the exit doors were locked from the inside, chained, bolted, barred, latched or otherwise rendered unusable at the time of the inspection;Y. inspect to determine whether the exit doors swing open in the direction of egress travel; andZ. inspect the storage to determine if it is potentially obstructing access to fire hydrants, fire extinguishers, alarm panels or electric panelboards, or if it is obstructing aisles, corridors, stairways or exit doors, or if it is within 18 inches of sprinkler heads, or if it is within 3 feet of heat-generating appliances or electrical panelboards.II. The inspector is not required to:A. test alarm systems, or determine if alarms systems have been tested.B. inspect or test heat detectors, fire-suppression systems, or sprinkler systems.C. determine the combustibility or flammability of materials in storage.D. determine the adequate number of fire extinguishers needed, or their ratings.E. test or inspect fire extinguishers, their pressure, or for the presence of extinguisher inspection tags or tamper seals.F. inspect or test fire pumps or fire department connections.G. inspect or test cooking equipment suppression systems.H. determine the operational time of emergency lighting or exit signs.I. inspect for proper occupant load signs.J. determine fire ratings of walls, ceilings, doors, etc.K. inspect, test or determine the adequacy of fire escapes or ladders.L. inspect fire department lock boxes or keys.M. determine the flame resistance of curtains or draperies.N. inspect parking or outdoor lighting.O. inspect for unauthorized entry or crime issues.P. inspect or test security systems.Q. inspect for pet or livestock safety issues.R. inspect for unsafe candle use or decoration hazards.S. inspect or test emergency generators.T. test kitchen equipment, appliances or hoods.U. verify that elevator keys exist, or that they work properly.6.5.13 Cooking AreaI. The inspector should:A. verify that all smoke- or grease-laden, vapor-producing cooking equipment, such as deep-fat fryers, ranges, griddles, broilers and woks, is equipped with an exhaust system;B. inspect for the accessibility for cleaning and inspection of the exhaust system’s interior surface;C. inspect for grease buildup;D. verify that hoods are made of steel or stainless steel;E. verify that visible grease filters are arranged so that all exhaust air passes through them;F. verify that visible sections of exhaust ducts are not interconnected with any other ventilation system;G. verify that visual sections of exhaust ducts are installed without dips or traps that might collect residue;H. verify that exhaust ducts do not appear to pass through firewalls;I. try to verify that exhaust ducts lead directly to the exterior of the building;J. try to verify that exterior exhaust outlets do not discharge into walkways, or create a nuisance, in the opinion of the inspector;K. inspect to determine that a portable fire extinguisher is stored within a 30-foot travel distance of commercial-type cooking equipment that uses cooking oil or animal fat; andL. inspect to determine that manual-actuation devices for commercial cooking appliances exist near the means of egress from the cooking area, 42 and 48 inches above the floor and 10 to 20 feet away, and clearly identifying the hazards protected.II. The inspector is not required to:A. determine proper clearances.B. determine proper hood size or position.C. test hoods.D. test exhaust fans or dampers, or measure air flow.E. test fire extinguishers, fire-extinguishing equipment, or fusible links.F. test kitchen equipment, appliances, hoods or their gauges.G. inspect or test grease-removal devices, drip trays or grease filters.H. inspect or test air pollution-control devices or fume incinerators.I. inspect or test kitchen refrigeration.J. inspect for fuel-storage issues.K. inspect, test or determine anything regarding food safety.L. issue an opinion regarding cooking operating procedures.

7.1 FormatThe report must be in writing. This Standard does not require any one particular format. It is the opinion of InterNACHI-CCPIA that the commercial inspection industry and consumer clients are best served when inspectors are free to compete through report-generation innovation.7.2 DateThe report should be dated on the first page.7.3 Inspection Firm InformationThe report should include the name and contact information of the inspection firm on the first or second page.7.4 Property AddressThe report should include the address of the property inspected, or a description of the real estate sufficient for identification, on the first or second page.7.5 Total Number of PagesThe report should indicate the total number of pages and attachments on the first page.7.6 BrevityReports should be concise, to-the-point, and avoid the inclusion of large amounts of pre-printed material.7.7 LegibilityReports should be typed or handwritten clearly.7.8 Opinions of Shut-Down SystemsThe inspector should still try to render an opinion of the condition of systems even if they were shut down or were not operational at the time of the walk-through survey.7.9 ObsolescenceThe client should only rely on the inspection report at the point in time that the inspector’s observations were being made and research was being conducted. The client should deem the report as obsolete to some extent, even while it is being prepared.7.10 Site-SpecificThe client should understand that an inspection performed in accordance with this Standard only relates to the observations made and research conducted. Consequently, this Standard does not address issues such as business operations at the subject property, deed encumbrances, neighborhood conditions, etc.7.11 Multiple BuildingsAn inspection report produced in accordance with this Standard may encompass more than one building within a single report.7.12 Cost to RemedyThe inspector is not required to provide repair estimates or opinions of costs to remedy. The inspector may offer opinions about such costs as a courtesy, but the offering of these opinions is outside the scope of a commercial inspection.

8. Limitations, Exceptions and Exclusions

8.1. Limitations:

I. An inspection is not technically exhaustive.

II. An inspection will not identify concealed or latent defects.

III. An inspection will not deal with aesthetic concerns or what could be deemed matters of taste, cosmetic defects, etc.

IV. An inspection will not determine the suitability of the property for any use.

V. An inspection does not determine the market value of the property, or its marketability.VI. An inspection does not determine the insurability of the property.

VII. An inspection does not determine the advisability or inadvisability of the purchase of the inspected property.VIII. An inspection does not determine the life expectancy of the property, or any components or systems therein.IX. An inspection does not include items not permanently installed.

X. These Standards of Practice apply only to commercial properties.8.2. Exclusions:I. The inspector is not required to determine:

A. property boundary lines or encroachments.

B. the condition of any component or system that is not readily accessible.

C. the service-life expectancy of any component or system.

D. the size, capacity, BTU, performance or efficiency of any component or system.

E. the cause or reason of any condition.

F. the cause of the need for repair or replacement of any system or component.

G. future conditions.

H. the compliance with codes or regulations.

I. the presence of evidence of rodents, birds, bats, animals, insects, or other pests.

J. the presence of mold, mildew, fungus or toxic drywall.

K. the presence of airborne hazards.

L. the presence of birds.

M. the presence of other flora or fauna.

N. the air quality.

O. the presence of asbestos.

P. the presence of environmental hazards.

Q. the presence of electromagnetic fields.

R. the presence of hazardous materials including, but not limited to, the presence of lead in paint.

S. any hazardous-waste conditions.

T. any manufacturers’ recalls, or conformance with manufacturers’ installations, or any information included for consumer-protection purposes.

U. operating costs of systems.

V. replacement or repair cost estimates.

W. the acoustical properties of any systems.

X. estimates of the cost of operating any given system.Y. resistance to wind, hurricanes, tornadoes, earthquakes or seismic activities.Z. geological conditions or soil stability.AA. compliance with the Americans with Disabilities Act.II. The inspector is not required to operate:

A. any system that is shut down.

B. any system that does not function properly.

C. or evaluate low-voltage electrical systems, such as, but not limited to:

- phone lines;

- cable lines;

- antennae;

- lights; or

- remote controls.

D. any system that does not turn on with the use of normal operating controls.

E. any shut off-valves or manual stop valves.

F. any electrical disconnect or over-current protection devices.

G. any alarm systems.

H. moisture meters, gas detectors or similar equipment.I. sprinkler or fire-suppression systems.III. The inspector is not required to:

A. move any personal items or other obstructions, such as, but not limited to:

1. throw rugs;

2. furniture;

3. floor or wall coverings;

4. ceiling tiles;

5. window coverings;

6. equipment;

7. plants;

8. ice;

9. debris;

10. snow;

11. water;

12. dirt;

13. foliage; or

14. pets.B. dismantle, open or uncover any system or component.

C. enter or access any area that may, in the opinion of the inspector, be unsafe.

D. enter crawlspaces or other areas that are unsafe or not readily accessible.

E. inspect or determine the presence of underground items, such as, but not limited to, underground storage tanks, whether abandoned or actively used.

F. do anything which, in the inspector’s opinion, is likely to be unsafe or dangerous to the inspector or others, or may damage property, such as, but not limited to, walking on roof surfaces, climbing ladders, entering attic spaces, or interacting with pets or livestock.

G. inspect decorative items.

H. inspect common elements or areas in multi-unit housing.

I. inspect intercoms, speaker systems, radio-controlled, security devices, or lawn-irrigation systems.J. offer guarantees or warranties.

K. offer or perform any engineering services.

L. offer or perform any trade or professional service other than commercial property inspection.

M. research the history of the property, or report on its potential for alteration, modification, extendibility or suitability for a specific or proposed use for occupancy.

N. determine the age of construction or installation of any system, structure or component of a building, or differentiate between original construction and subsequent additions, improvements, renovations or replacements thereto.

O. determine the insurability of a property.P. perform or offer Phase 1 environmental audits.Q. inspect or report on any system or component that is not included in these Standards.

Core Definitions

2.1.1 Commercial Property: A commercial property is defined as the building structures and improvements located on a parcel of commercial real estate. These may include structures such as buildings with residential units operated for profit, mixed-use buildings, strip malls, motels, factories, storage facilities, restaurants and office buildings.

2.1.2 Inspection: The inspection is defined as the process of an inspector collecting information through visual observation during a walk-through survey of the subject property, conducting research about the property, and then generating a meaningful report about the condition of the property based on the observations made and research conducted by the inspector. A commercial inspection requires the inspector to make observations, conduct research, and report findings.

2.1.2.1 Observations: Observations are defined as those potential items of interest noted by the inspector during the walk-through survey portion of the inspection.2.1.2.2 Research: Research is defined as the process of gathering information through document review and interviews to augment the observations made during the walk-through portion of the inspection. This research may include reviewing readily available documents, such as previous inspection reports, building permits, code violation notices and environmental studies. This research may also include interviews with readily available personnel, such as building managers, tenants and owners.2.1.2.3 Report: An inspection report is defined as a written communication describing the issues discovered from observations made and research conducted by the inspector that are, in the inspector’s opinion, likely to be of interest to his/her client. A report may contain photographs of observations made during the walk-through survey portion of the inspection and/or copies of documents reviewed during the research portion of the inspection.

2.2 Terminology Commonly Found in Commercial Property Inspection Reports:

- above-grade wall: a wall that is mostly above grade and enclosing conditioned space.

- access: that which enables a device, appliance or equipment to be reached.

- access panel: a closure device used to cover an opening into a duct, an enclosure, or equipment.

- accessibility: level of access a building offers people with disabilities.

- accessible: in the opinion of the inspector, can be approached or entered safely without difficulty, fear or danger.

- accessory structure: an additional building to the primary building.

- activate: to turn on, supply power, or enable systems, equipment or devices to become active by normal operating controls; examples include turning on the gas or water supply valves to fixtures and appliances, or activating electrical breakers or fuses.

- actual knowledge: the knowledge possessed by an individual, as opposed to that discovered through document review.

- addition: an extension or increase in the conditioned space of a building.

- adverse conditions: conditions that may be dangerous for the inspector and may limit the walk-through survey portion of the inspection.

- adversely affect: to constitute, or potentially constitute, a negative or destructive impact.

- air intake: an opening in a building’s envelope whose purpose is to allow outside air to be drawn in to replace inside air.

- aisle: an exit access component that provides a path of egress travel.

- alarm signal: a signal indicating an emergency, such as a fire, requiring immediate action.

- alarm system: warning devices, installed or freestanding, including, but not limited to: carbon-monoxide detectors, flue gas and other spillage detectors, security equipment, ejector pumps and smoke alarms.

- alteration: any construction or renovation to an existing structure other than a repair or addition; also, a change in a mechanical system.

- appliance: utilization equipment, generally other than industrial, that is installed or connected as a unit to perform one or more functions.

- approved: acceptable to the authority having jurisdiction; also, accepted by an internationally recognized organization, such as InterNACHI.

- arc-fault circuit interrupter (AFCI): a device intended to provide protection from the effects of arc faults by recognizing characteristics unique to arcing, and by functioning to de-energize the circuit when an arc fault is detected.

-

authority having jurisdiction (AHJ): an organization, office, or individual responsible for enforcing the requirements of a code or standard, or for approving equipment, materials, an installation, or a procedure. The AHJ is often the building owner, health department, insurance agent, or fire marshal.

-

automatic: that which provides a function without the necessity of human intervention.

-

automatic fire-extinguishing system: a system of devices and equipment that automatically detects a fire and discharges in an attempt to put it out.

-

automatic sprinkler system: an automated sprinkler system for fire-protection purposes.

-

balcony: exterior floor projecting from and supported by a structure without additional independent supports.

-

band joist: dimensional lumber used as a perimeter joist of the building framing.

-

basement: that portion of a building which is partly or completely below grade.

-

basement wall: a wall of a building that is mostly below grade.

-

bathroom: a room containing plumbing fixtures, such as a water closet, urinal, bathtub and/or shower.

-

bedroom: a room used for sleeping purposes.

- bidet: a toilet-like plumbing fixture designed to promote posterior hygiene; not a toilet.

-

bonding: the permanent joining of metallic parts to form an electrically conductive path that ensures electrical continuity, and the capacity to conduct safely any fault current likely to be imposed.

-

branch circuit: the circuit conductors between the final over-current device protecting the circuit and the outlet(s).

-

building: the primary building subject of the commercial inspection.

-

building code: rules and regulations adopted by the governmental authority having jurisdiction over the construction and/or remodeling of the commercial property.

-

building department: local authority having jurisdiction over the construction, alteration and use of a property.

-

building envelope: the enclosure that defines the heated/cooled area of a building, namely, the exterior walls and roof.

-

building systems: components, assemblies and systems that are a part of the overall building and property such as pavement, flatwork, structural components, roofing, exterior walls, plumbing, HVAC, electrical components, fire prevention, etc.

- built-in: permanently installed.

- chimney: a structure containing one or more flues for removing gases to the outside atmosphere.

- cladding: something that covers or overlays, often used to describe exterior wall coverings or metal that covers windows, doors or fascia for weather protection.

- cleanout: an accessible opening in the drainage system used for the removal of possible obstructions and for inspections; an opening in a chimney that provides access to the flue for cleaning purposes.

- clearance: the minimum distance through air measured between the surface of something heat-producing and the surface of something combustible.

- clearly identifiable: capable of being recognized by a person of normal vision.

- client: the party that retains the inspector and pays for the inspection.

- code official: the officer or other government-designated authority charged with enforcement of building codes.

- combustible: describes any material that will burn.

- commercial cooking appliances: appliances used in a commercial food service establishment for heating or cooking food.

- commercial property: the building structures and improvements located on a parcel of commercial real estate. These may include structures such as buildings with residential units operated for profit, mixed-use buildings, strip malls, motels, factories, storage facilities, restaurants and office buildings.

- component: a permanently installed or attached fixture, element, or part of a system.

-

concealed: rendered inaccessible by the structure or finish of the building. Wires in concealed raceways are considered concealed, even though they may become accessible by withdrawing them.

-

condition: the plainly visible and conspicuous state of being of a material object or thing.

-

conditioned space: an area or room within a building being heated or cooled.

-

connector: the pipe that connects a fuel-burning appliance to a chimney.

- consultant: a person with particular expertise in a subject who assists the inspector with portions of the inspection.

- contamination: an impairment of the quality of the potable water.

- crawlspace: the area within the confines of the foundation and between the ground and the underside of the lowest floor’s structural component.

- cross-connection: any connection between two otherwise separate piping systems, one of which contains potable water, and the other that contains something that could contaminate the potable water.

- crown: the sloped top of a masonry chimney designed to shed water away from the flue; also called a splay or a wash.

- damper: a valve or plate for controlling draft or flow of gases, including air, in a vent or ductwork; a manually-operated plate for controlling draft in a flue.

- deck: exterior floor system supported on at least two opposing sides by an adjoining structure and/or post, piers, or other independent supports.

- decorative: ornamental; not required for the operation of essential systems and components of a building.

- defensible space: an area around a building designed to slow the rate of an advancing wildfire.

- deferred-maintenance items: deficient items that cannot be remedied with routine maintenance, generally caused by neglect.

- describe: to report, in writing, a system or component by its type or other observed characteristics to distinguish it from other components used for the same purpose.

- destructive: an act of demolishing, damaging or probing any system, structure or component, or to dismantle any system or component that would not be taken apart by an ordinary person in the course of normal maintenance.

- determine: to arrive at an opinion or conclusion pursuant to examination.

- disconnected: shut down.

- dismantle: to open, take apart or remove any component, device or piece that would not typically be opened, taken apart, or removed by an ordinary occupant.

- duct: a passageway, tube or conduit utilized for the transmission of air and vapors.

- due diligence: a level of care in the inspection process that varies, depending upon the scope of work agreed upon by the inspector and his/her client.

- dwelling unit: a single unit providing complete, independent living facilities, including permanent provisions for living, sleeping, eating, cooking and sanitation.

- easement: that portion of a land or property reserved for use by a person or agency other than the owner of the property.

- easily visible: describes systems, items and components that are both conspicuous and in plain sight, absent of the need for intrusive inspection techniques, probing, disassembly, or the use of special equipment.

- egress: a means of exiting.

- emergency shutoff valve: a valve designed to shut off the flow of gases or liquids.

- energy analysis: a method for estimating the annual energy use of a building.

- energy-recovery ventilation system: a system that uses air-to-air heat exchangers to recover energy from exhaust air for the purpose of pre-heating or pre-cooling outdoor air prior to supplying the air to an interior space.

- engineering service: any professional service or creative work requiring engineering education, training and experience, and the application of special knowledge of the mathematical, physical and engineering sciences to such professional service or creative work as consultation, investigation, evaluation, planning, design and/or supervision of construction for the purpose of assuring compliance with the specifications and design, in conjunction with structures, buildings, machines, equipment, works or processes.

- enter: to access or go into an area to observe visible components.

- evaluate: to assess the systems, structures and/or components of a building.

- evidence: plainly visible and conspicuous material objects or other things presented to the senses that would tend to produce conviction in the mind of an ordinary person as to the existence or non-existence of a fact.

- examine: to visually examine; to look for and identify material physical deficiencies in systems, structures or components of a building through a non-intrusive physical inspection. See inspect.

- existing: buildings, facilities or conditions which are already in existence. This Standard is designed to be used to inspect existing commercial properties.

- exit discharge: the portion of a means of egress between the termination of an exit and a public way.

- exposed: capable of being inadvertently touched by a person because it is not suitably guarded, isolated or insulated.

- exterior property: the open space on the property.

- exterior wall: an outside wall of a building, either above or below grade.

- extermination: the control or elimination of insects, rats, vermin or other pests.

- fenestration: products with glass and non-glass glazing materials, including skylights, roof windows, vertical windows, opaque doors, glazed doors and glazed block.

- fire apparatus access road: a road, fire lane, public street, private street, or parking lot lane that provides access from a fire station to a facility.

- fire code official: the fire chief or other authority charged with the enforcement of a code.

- fire department master key: a special key carried by fire department officials which will open key boxes on commercial properties.

- fire-resistance rating: the time that materials or assemblies can withstand fire exposure.

- fireplace lintel: a horizontal, non-combustible member that spans the top of the fireplace opening.

- firewall: a wall separating buildings or subdividing a building to prevent the spread of fire.

- fixture: component.

- flood-level rim: the edge of a fixture from which water overflows.

- floor area, gross: the floor area within the inside perimeter of the exterior walls.

- floor area, net: the actual occupied area not including accessory areas, such as corridors, stairways, restrooms, mechanical rooms and closets.

- flue: a passage through which gases move from the fire chamber to the outer air.

- foundation: the base upon which the structure or wall rests (usually masonry, concrete or stone), and generally partially underground.

- function: the action for which an item, component or system is specially fitted or used, or for which an item, component or system exists; to be in action or perform a task.

- functional: performing, or able to perform, a function.

- functional drainage: the emptying of a plumbing fixture in a reasonable amount of time without overflow when another fixture is drained simultaneously.

- functional flow: a reasonable flow of water supply at the highest and farthest fixture from the building main when another fixture is operated simultaneously.

- further evaluation: a degree of examination beyond that of a typical and customary, non-intrusive physical examination.

- fusible link: a form of fixed-temperature heat-detecting device sometimes used to restrain the operation of an electrical or mechanical control until a certain temperature is reached, usually signifying a fire.

- garbage: the animal or vegetable waste resulting from preparation or consumption of food.

- grease: animal fat, vegetable shortening or oil used in preparing food or resulting from cooking.

-

grounded: connected to the earth or to some conducting body that serves in place of the earth.

-

grounded, effectively: intentionally connected to the earth through a ground connection or connections of sufficiently low impedance, and having sufficient current-carrying capacity to prevent the buildup of voltages that might otherwise result in undue hazards to connected equipment or to persons.

-

ground-fault circuit interrupter (GFCI): a device intended for the protection of personnel that functions to de-energize a circuit.

-

grounding electrode: a device that establishes an electrical connection to the earth.

-

habitable space: space in a structure for living, sleeping, eating and/or cooking. Bathrooms, closets, halls, storage areas and utility spaces are not considered habitable spaces.

-

hearth: the floor within a fireplace.

-

hearth extension: non-combustible material in front of and at the sides of a fireplace opening.

-

heated slab: slab-on-grade construction in which the heating elements are placed within or under the slab.

-

hood: a device that directs and captures grease-laden vapors and gases from a cooking appliance.

-

humidistat: a device used to automatically control relative humidity.

-

identify: to notice and report.

-

immediate cost: estimated cost of remedying an existing safety hazard, or repairing a system or component that will likely fail within a year.

-

imminent danger: a condition which could cause serious or life-threatening injury or death.

-

infestation: the presence of insects, rats, vermin or other pests.

-

infill: area of the railing system bounded by the railing posts, cap, rail and the deck.

-

infiltration: the uncontrolled inward air leakage into a building.

-

inspect: to examine readily accessible systems and components safely, using normal operating controls, and accessing readily accessible areas, in accordance with these Standards of Practice.

- inspected property: the readily accessible areas of the buildings, site, items, components and systems included in the inspection.

- inspection: the process of an inspector collecting information through visual observation during a walk-through survey of the subject property, conducting research about the property, and then generating a meaningful report about the condition of the property based on the observations made and research conducted by the inspector. A commercial inspection requires the inspector to make observations, conduct research, and report findings.