Building Supporters Services

High Performance Colorado Inspection Report Review: Second Opinion + Re-Inspections

Building Supporters Services

High Performance Colorado Inspection Report Review: Second Opinion + Re-Inspections

When clarity and precision are key to making an intelligent decision, settling for the standard is...

Schedule now. Get transparent pricing plus instant, easy online scheduling.

Get Your ePriceThese systems are crucial for the sanitation needs of these houses, operating through a process that involves various components and stages. Understanding and maintaining these systems is vital to avoid potential inconveniences and financial burdens in the future.

Additionally, these tests can potentially prove invaluable in disputing seller claims regarding the source of stinky water puddles in yards, revealing septic system leaks. Plus, Building Supporters’ septic testing can potentially unmask any direct or indirect discharges of the system to the ground surface, ditches, streams, etc., highlighting environmental concerns. Inspections are only done for septic systems installed after 1997, due to systems having a certain standard of modernity and regulation compliance.

The operation of a septic system begins with waste from the household being transported through a main waste line into the septic tank. Here, the waste undergoes a breakdown process over time. As the breakdown progresses, liquid effluent separates and rises to the top, eventually flowing out towards distribution boxes and into the leach field, a critical component of the septic system.

To ensure the functionality and efficiency of these systems, it’s advisable to conduct a comprehensive visual inspection, which includes several key tests:

Visual equipment and component inspection: Technicians begin with the septic tank, looking for cracks, leaks, or signs of corrosion. They pay special attention to the tank’s lids and covers, ensuring they are secure and intact to prevent unauthorized access and to maintain safety.

• Baffles and T-Pipes: Baffles and T-pipes play critical roles in directing the flow of waste and effluent within the septic system. Inspectors assess these components for blockages, deterioration, or improper installation that could disrupt the system’s efficiency. Ensuring these elements are in good condition is vital to facilitate the correct separation of solids and liquids in the tank.

• Distribution Boxes: Distribution boxes must evenly distribute effluent to the leach field. Visual checks include looking for cracks, signs of settling, or blockages that could lead to uneven distribution or overflow. Proper alignment and slope of the distribution lines from these boxes are also verified to ensure the effluent is correctly directed toward the leach area.

• Pump and Alarm: For systems equipped with pumps and alarms, a visual and operational check is conducted. Inspectors ensure that pumps are not corroded or seized and that electrical connections are safe and intact. Alarms are tested to confirm they are operational and correctly alert homeowners of potential issues like high water levels.

• General Cleanliness and Maintenance: A visual assessment of the system’s cleanliness and the surrounding area can provide insights into regular maintenance practices. Indications of neglect could suggest potential problems or a lack of maintenance that might impact the system’s longevity and performance.

Flow Test: This initial test checks if the sanitary pipe correctly delivers liquid to the septic system. By observing how water from the test integrates with the system, technicians can assess whether effluent efficiently flows out through the system’s baffles into the leach field. Insufficient water flow may indicate a plumbing issue within the home, necessitating an inspection of each water source. Conversely, a rapid rise in water level in the tank could signal problems downstream.

Tank Inspection: Technicians then evaluate the septic tank itself, focusing on the accumulation of scum, sludge, solids, and the effluent level. Ideally, scum and sludge layers should each constitute about 30% of the tank’s volume, with effluent making up the final 40%. A discrepancy in these proportions may point to issues, particularly with the leach field.

Leach Field Examination: The leach field is visually inspected for any surface signs of system backup or failure, such as standing water (not attributable to recent rainfall) or unusually lush vegetation, which may indicate effluent surfacing. Observing for odors or soggy ground can also point to potential issues. The use of a probing device allows the technician to assess hydraulic stress, indicating whether the field is experiencing flooding.

Included Advanced Testing Strategies: Septic Dye Test combined with a Hydraulic Loading Test: Hydraulic load testing adheres to the National Association of Wastewater Transporters’ recommendation; this process involves introducing an estimated average daily flow of sewage (a minimum of 100 gallons) into the system.

The septic dye test involves introducing a highly visible fluorescent dye, along with a substantial volume of water, typically equivalent to the average daily water usage of the household, into the system. The dye is flushed down a toilet or sink, entering the septic tank and then moving through the system towards the leach field. Inspectors observe the area around the septic system and the leach field for signs of the brightly colored dye. Ground surface appearances of the dye can indicate issues such as leaks in the septic tank, problems with the distribution box, or a failure in the leach field to adequately absorb the effluent.

While not exhaustive, these tests are instrumental in evaluating the septic system’s performance without resorting to more extensive excavation or disruption to the homeowner’s property. However, it’s important to acknowledge possible interpretation issues, such as the level of effluent ponded in trenches. Jurisdictions differ in their views on effluent ponding, with some considering any level of ponding as a system failure.

High performance septic inspections:

Have questions, unusual complexities or demanding requirements? Contact us for fast same/next day proposals and answers.

(* Inspections are only done for septic systems installed after 1997, due to systems having a certain standard of modernity and regulation compliance.)

We cover a 75+ mile radius of Boulder: Same-day reports. Fully Insured. Save more money: We inspect, test, report, and protect more - way more. The difficult done immediately. The impossible takes a little longer. Miracles by appointment. Schedule today.

Building Supporters Services

High Performance Colorado Inspection Report Review: Second Opinion + Re-Inspections

Building Supporters Services

High Performance Colorado Inspection Report Review: Second Opinion + Re-Inspections

When clarity and precision are key to making an intelligent decision, settling for the standard is...

Building Supporters Services

High Performance Nationwide Remote Inspection Report Review: Second Opinion

Building Supporters Services

High Performance Nationwide Remote Inspection Report Review: Second Opinion

When you’re making crucial decisions about property investments, the accuracy and clarity of your inspection report...

Building Supporters Services

High Performance Nationwide Remote Inspection: Live Video Consultation

Building Supporters Services

High Performance Nationwide Remote Inspection: Live Video Consultation

Ready to revolutionize the way you handle your property challenges? Forget waiting; let’s dive straight into...

Building Supporters Services

High Performance Nationwide Remote Inspection: Photo/Video Evaluation

Building Supporters Services

High Performance Nationwide Remote Inspection: Photo/Video Evaluation

Elevate your property experience with ultra-responsive remote evaluation services. When you need instant answers, we’re here...

Building Supporters Services

High Performance Colorado Commercial Inspections, Building Surveys + Condition Assessments

Building Supporters Services

High Performance Colorado Commercial Inspections, Building Surveys + Condition Assessments

Unparalleled due diligence to maximize your investment: Your ultimate safeguard against the cascade of potential pitfalls...

Building Supporters Services

High Performance Colorado Pre-Purchase Residential Home Inspections

Building Supporters Services

High Performance Colorado Pre-Purchase Residential Home Inspections

Whether it’s your first home or fifth, dream home or just a stepping stone, make sure...

Building Supporters Services

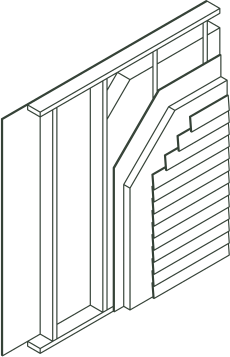

High Performance Colorado Residential New Home Construction Inspections (Pre-Drywall & Phases)

Building Supporters Services

High Performance Colorado Residential New Home Construction Inspections (Pre-Drywall & Phases)

The best money you will ever spend while constructing a new home. Period. Full stop. In...

Building Supporters Services

High Performance Colorado Pre-Listing Inspections

Building Supporters Services

High Performance Colorado Pre-Listing Inspections

It’s not a matter of IF defects are found, but rather WHEN. No matter how picture-perfect...